Do you encounter such problems when using oil sensors:

- Lack of consistency in viscosity representation and lack of comparability of results? Part of the mechanical calculation of fixed density values into kinematic viscosity, because density changes with temperature, dynamic viscosity and density measurement is not scientific!

- The sensor has low measuring range and is difficult to meet the industrial demand

- The sensor detection parameters are too single

- The price is expensive, the installation is inconvenient, the maintenance is complex

- Low accuracy of measurement

- Low reliability, difficulty in meeting the demands of complex operating conditions and so on

If you have the above problems and are looking for ways to solve them, Yateks’s online oil monitoring system can help you solve all of them!

Whether it is lubricating oil, hydraulic oil, gear oil, gasoline, diesel, jet fuel, biodiesel, etc., whether you are in food processing, laboratory, fuel oil storage, oil refining, aviation, navigation, railway or petroleum processing equipment, medical Equipment, coatings and other industries, Yateks’s online oil monitoring system can provide you with powerful help!

There is no doubt that we can provide you with the following help:

1.Real-time Following up and monitoring the wearing state and changing trend of equipment.

2.Providing the scientific basis for equipment management operator make machine halt maintenance plan and extensive maintenance plan.

3.Achieving maximum machinery and lubricant efficiency, could detect and repair the hidden fault in time, and extend the period of extensive maintenance.

4.Users benefit from reduced operational and maintenance costs, efficient productivity

5.Online Oil Monitoring System combines multiple sensor functions in one, which can automatically detect the moisture, density, viscosity, dielectric constant, water activity, oil consumables and temperature. The data collected internally in real time is analyzed and processed by wired or wireless means and sent to the monitoring terminal and the cloud, which can be monitored remotely by mobile phone or computer.

6.No installation is required. Integrated with a variety of sensors according to customer’s demands.We have already assembled all the parts for you. You can quickly get the test results by connecting to the oil to be tested when you turn on the machine!

7.Professional services and tutorial guidance help you quickly understand the machine and also provide you with professional advice!

Here are the features you want to know:

1.Combined 6 in 1 oil and particle counter sensors, which can automatically detect the moisture, density, viscosity, dielectric constant, water activity, oil consumables and temperature, as well as particle quantity, Helping you understand all aspects of oil parameters in detail!

2.Standardization of non-standard products: Connected to the oil circuit, Easy to operate with one key touching to start and real-time monitoring and detecting.

3.Free choice of wired/ 4G wireless transmission, automatic warning in the background; free storage in the cloud, real-time computer/phone viewing. Convenient for your fast monitoring anytime, anywhere!

4.Wide range of detection, high accuracy, and can meet the requirements of accurate and efficient monitoring task.

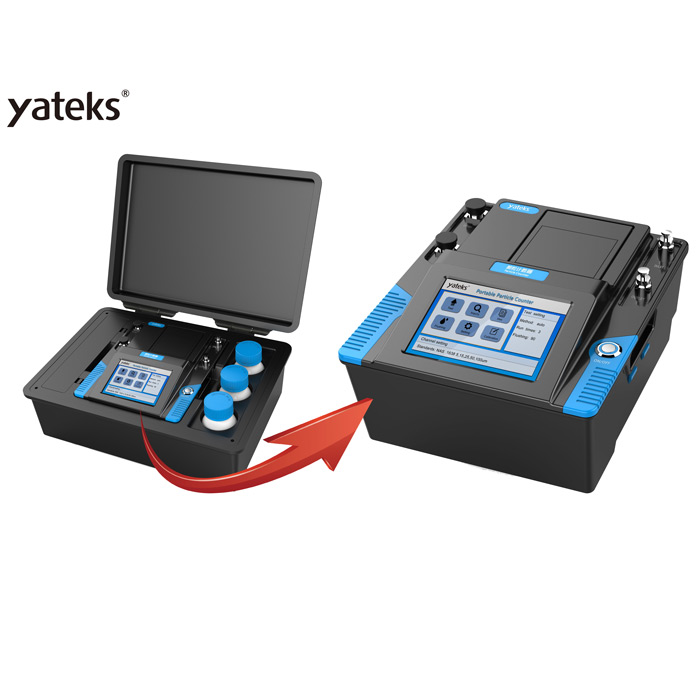

5.Size: 352*278*160mm, 13KG, die-casting aluminum.

6.Included items: 7 inch display screen, software, oil tubes, oil grooves, wiring and circuit design, fixtures, LED indicator(Red/Green/Yellow) for alarm function etc

7.Whether on-line monitoring or off-line monitoring, the ultimate goal is to form effective and instructive equipment management opinions, how to summarize and analyze simple data into the analysis conclusion of equipment adjustment and management, this requires a large number of data samples and modeling.

8.The company has enriched its oil monitoring and analysis for more than 20 years. It has a high-tech team led by academicians. The company’s advanced algorithms and analysis methods are playing their own advantages in our national defense construction and economic construction, promote the industry’s previous development

In addition to powerful functions, we also have comprehensive after-sales and maintenance services, we can provide online support in time to meet customer demands at any time.

Online meeting, online presentation, online demonstration, online training, etc.

As long as you need us, we’ll always here for your full support.

We also have more oil monitoring tools to meet your various needs in different situations, such as Portable Particle counter Quick Oil Quality Analyzer Economy Ferrograph Microscope Oil Micro-Moisture Sensor Oil Particle Counter Sensor and various sensors, more detailed and powerful For the specific test data range, please go to https://www.yateks.com/ to view!

If you have any questions about products and technology, please contact us directly, we will serve you sincerely. Thank you for your trust and support!