Gearbox is an important part of industrial power transmission, and it is also a mechanical equipment with a high incidence of wear failure. Take the speed-increasing gearbox of a wind farm as an example. The speed-increasing gearbox is at the top of the wind tower and is in unattended operation on weekdays. Good lubrication is an important condition to ensure the safe operation of the gearbox. Therefore, the “oil online monitoring system” is installed. “It is an important guarantee for the normal operation of the fan speed-increasing gearbox. The gearbox oil online monitoring system can be widely used in petrochemical, cement, steel, port and other industries.

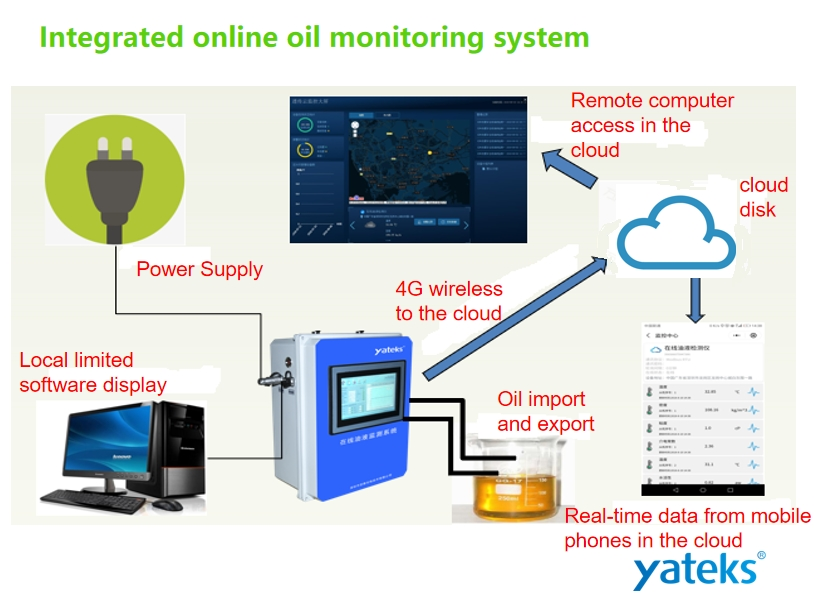

The online monitoring of gearbox oil is very convenient. You only need to install a lightweight online monitor on the outer circulation loop of the gearbox, and the data obtained can be sent to the maintenance staff’s operating room through wireless transmission or wired transmission, without the need for operation and maintenance engineers Potential lubrication and wear failures of various gearboxes can be discovered in time on site.

Main technical indicators of “Gearbox Oil Online Monitoring System”

(1) Oil viscosity: using fluid vibration sensing technology to detect the viscosity change of gear oil, when the gear oil is contaminated by hydraulic oil due to refueling error or seal damage, it can be discovered and alarmed in time.

(2) Pollution of moisture: using polymer film capacitance sensing technology to detect changes in trace moisture in gear oil. When the gearbox is contaminated by trace moisture due to respiration, it can be discovered in time to avoid the formation of condensed water.

(3) Wear particles: Use abrasive particle detection technology to detect the wear of gearbox steel tooth surfaces and non-ferrous metal rolling bearing cages, and find early failures such as pitting fatigue, adhesive wear and cage deformation and cracking on the tooth surfaces in time.

(4) Oil quality: Adopt liquid dielectric constant sensing technology to detect the deterioration of gear oil. Avoid the deterioration of the working performance due to the oxidation of the gear oil, resulting in poor lubrication of the gear box.

(5) Oil contamination: The optical particle counting technology is used to detect the concentration of contaminated particles in the gear oil. When the grit dust in the air enters the gear box through the damage, it can be found in time to avoid scratches and fatigue on the tooth surface.

(6) System configuration: According to customer needs, the above sensing technologies can be used alone or in combination with multiple sensing technologies to obtain comprehensive lubrication and wear status information of Fengdian gearboxes.

Yateks oil online monitoring system is easy to install on site: it can be used when it is brought to the site and connected to the oil circuit without complicated secondary development. Modular design: The collection terminal can be selected in a variety of combinations, in any combination, and sensors can be configured according to customer conditions; the detection range is wide, which solves most of the pain points of small detection range and low accuracy of online monitoring devices on the market. At the same time, it supports free selection of wired/wireless transmission and automatic warning in the background.