Release Date: 2016-03-14

Views: 55

What is meant by abrasion resistance?

Abrasion-resistant refers to the ability of materials or structures to withstand any method of wearing down or rubbing away by means of friction. This ability helps the material maintain its original structure and appearance, and resist mechanical wear.

What is wear analysis?

The friction is the predominant factor causing deterioration of your equipment, abrasion and wears testing will give you data to compare materials or coatings and can help you predict the lifetime of a material or coating. Abrasion testing is used to test the abrasive resistance of solid materials.

How to Establish a Friction and Wear Analysis Lab?

Friction and wear analysis laboratory is a professional laboratory for friction and wear and oil testing. It is including oil physical and chemical analysis system, oil wears testing and sample simulation testing machine. By testing lubricant, we could analyze joint friction and wear lifespan of locomotive and diesel engine.

An infrared spectrometer, kinematic viscosity meter, oil acid value analyzer, and water determination composes lubricant monitoring system. It could analyze the content, viscosity, and power of hydrogen. On the basis of such testing data, we could full-scale understand the lubrication condition of joint friction, study the reason for friction and wear to provide a way of fixing.

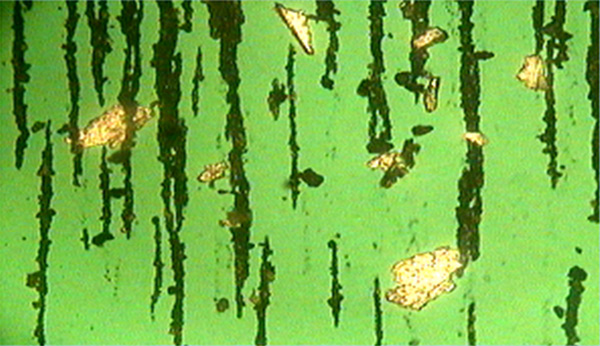

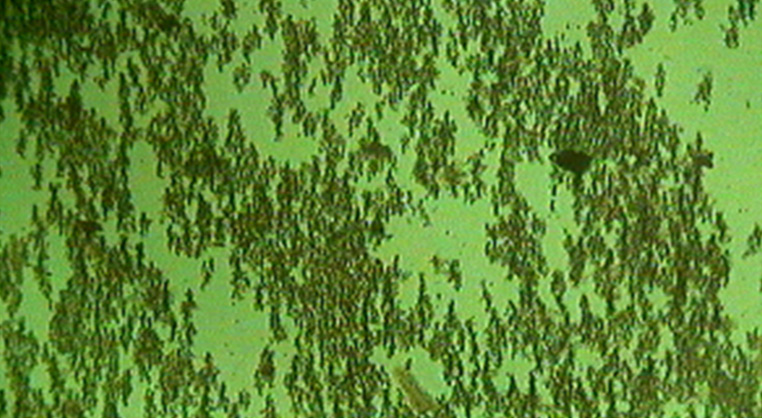

Spectrum analyzer, ferrography, ferrous debris monitor, particle count forms oil analysis system. Ferrography can show the shape, size, content. Spectrum can test abrasive dust, pollutant, 19 elements of additive and provide the technical data of wear level.

Sample simulation testing machine includes high-speed ring block wear testing machine, four ball extrusion friction tester, pin-on-disk wear testing machine. It uses for joint friction experiment of friction performance, the load capacity of lubricant carrying capacity test, friction pair bonding resistance test to research the antiwear property of friction surface.

Yateks oil testing lab could provide full service of oil analysis consult. And also we produce high-quality ferrography, ferrous debris monitor, quick oil quality analyzer, and etc. to help you study the condition of your oil and reason to improve performance.