Condition Based Monitoring:

Oil Analysis

Oil analysis is a routine activity for analyzing oil health, oil contamination and machine wear. The purpose of an oil analysis program is to verify that a lubricated machine is operating according to expectations. When an abnormal condition or parameter is identified through oil analysis, immediate actions can be taken to correct the root cause or to mitigate a developing failure.

1.Why Perform Oil Analysis?

An obvious reason to perform oil analysis is to understand the condition of the oil, but it is also intended to help bring to light the condition of the machine from which the oil sample was taken. There are three main categories of oil analysis: fluid properties, contamination and wear debris.

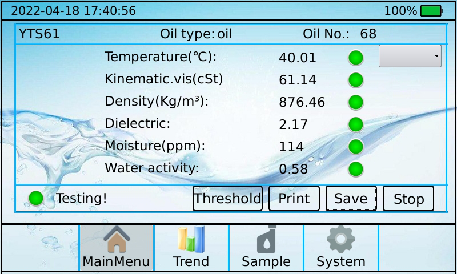

2.Fluid Properties

This type of oil analysis focuses on identifying the oil’s current physical and chemical state as well as on defining its remaining useful life (RUL). It answers questions such as:

Does the sample match the specified oil identification?

Is it the correct oil to use?

Are the right additives active?

Have additives depleted?

Has the viscosity shifted from the expected viscosity? If so, why?

What is the oil’s RUL?

3.What does the oil contamination analysis include?

By detecting the presence of destructive contaminants and narrowing down their probable sources (internal or external), oil analysis can help answer questions such as:

Is the oil clean?

What types of contaminants are in the oil?

Where are contaminants originating?

Are there signs of other types of lubricants?

Is there any sign of internal leakage?

YFJ-4 on-line particle counter sensor is developed based on the light blockage method method (photoresistance method) principle, which is used for on-line real-time monitoring of particle pollution in the oil circuit of hydraulic system.

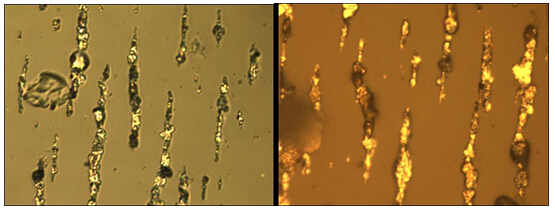

4.Wear Debris

This form of oil analysis is about determining the presence and identification of particles produced as a result of mechanical wear, corrosion or other machine surface degradation. It answers questions relating to wear, including:

Is the machine degrading abnormally?

Is wear debris produced?

From which internal component is the wear likely originating?

What is the wear mode and cause?

How severe is the wear condition?

In general, it can be said that, Oil analysis for machines can be compared to blood analysis for the human body.

Yateks YTF-8 Dual Slide Analytical Ferrography can quickly judge the operation and wear status of the equipment and the trend of oil changes through spectrum; with the help of ferrography analysis software, it can accurately determine the location and cause of wear failure.

5.Oil Analysis Tests

Routine tests vary based on the originating component and environmental conditions but should almost always include tests for viscosity, elemental (spectrometric) analysis, moisture levels, particle counts, Fourier transform infrared (FTIR) spectroscopy and acid number. Other tests that are based on the originating equipment include analytical ferrography, ferrous density, demulsibility and base number testing.

Yateks ,manufacturer of oil analysis products and solution provider for around 20 years. If you have any questions,please don’t hesitate to contact us.