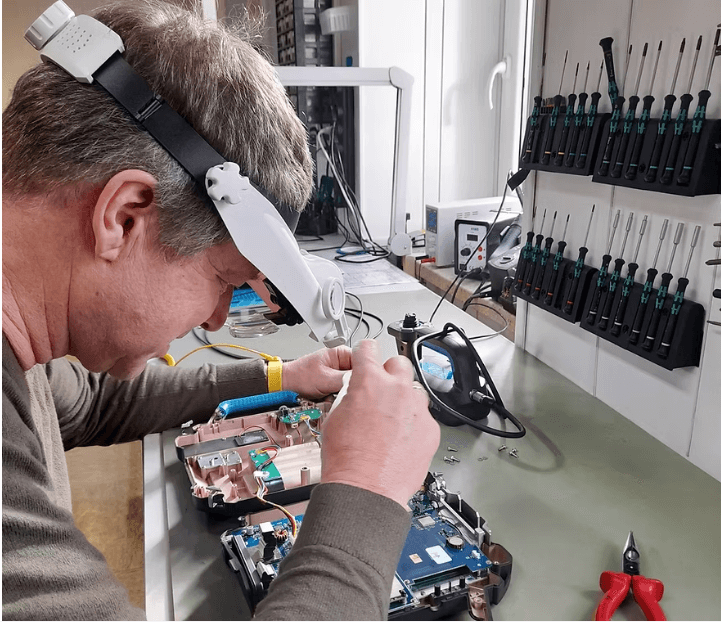

The main function of the industrial endoscope is non-destructive testing. The main objects are the interior of various pipelines, the interior of instruments and equipment, etc. The main defects that can be identified are cracks, white spots, sand holes, pores and slag inclusions;

Due to the complex use environment of industrial video endoscopes, the type of endoscope used is usually determined according to the location and requirements of the specific detection object, at least the location, direction, access and other elements of the detection must be considered. Especially complex detection products often require Various types of endoscopes are used together.

In addition to aerospace, automobile maintenance, wind power industry, etc., the pharmaceutical manufacturing industry is also very important for regular inspection; because in the process of pharmaceutical equipment production and pipeline installation, in order to control the quality of pipelines and engineering, in order to provide qualified products that meet the standards , its primary key task is to provide high-quality, safe and reliable pipeline welding reports, and various certification systems implement reasonable and effective whole-process management and control of pipeline welding quality.

To achieve the purpose of control, it is necessary to find out the welding defects that affect the medium conveying environment and how to control these welding defects in the actual production process.

So what tests do the prices of industrial endoscopes need to be done on pharmaceutical equipment pipelines?

The pipeline of the manufacturing equipment must be kept highly clean. If there is a defect in the interior and the human eye cannot observe it, then after the pipeline is put into use, the residue, residue, dirt, rust, etc. inside the pipeline will affect the quality of the medicine, causing Not to mention the waste of resources, it will also affect the quality of medicines and cause immeasurable damage;

- Intracavity inspection. Check for surface cracks, peeling, pulling wires, scratches, pits, bumps, spots, corrosion and other defects.

- Weld surface defect inspection. Check the weld surface for cracks, lack of penetration and weld leakage.

- Status check. When certain products (such as worm gear pumps, engines, etc.) work, endoscopy is carried out according to the items specified in the technical requirements.

- Excess inspection. Check the residual internal chips and foreign objects in the inner cavity of the equipment pipeline.

If you have relevant testing needs, please come to Yateks for consultation.