Industrial Borescope Camera

Our industrial borescope can meet the requirements of most industries. We will provide you with the best endoscope camera. We produce the best endoscopes. Borescope inspection can save you a lot of unnecessary trouble. Besides, the after-sale service of industrial borescope is perfect. If you need the best borescope inspection camera, Yateks is your first choice. Here are the best endoscopes, best endoscope inspection cameras, and portable endoscopes.

For each of the following industrial endoscopes, we have provided you with the most detailed borescope inspection scope introduction. Here are detailed data on the best endoscope, best endoscope inspection camera, and portable endoscope. If you want to know each endoscope definition’s specific data, you can click on the link to read it.

- Optional diameter: 2.2mm,2.8mm,4mm,6mm ;Forward view;dual camera;White light and ultraviolet light

- LED illumination way, brightness is up to 10000lux

- The camera module head adopts 316 stainless material

- UV borescope with the 365nm UV waveband

- ultraviolet light power ≥60mW can achieve 4-meter.

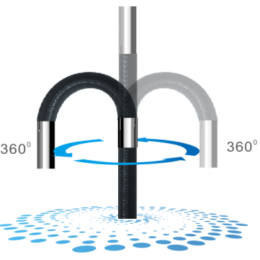

- Mechanical 360°articulation and weighs only 0.75kg.

- 3D measurement system can accurately measure the size of defects

- Automatic locking and precise positioning

- 4-way 360° articulation with stepping function

- Built-in four color modes

- Outstanding temperature detection function

- Unique interchangeable camera and tube

- Special dual light compensation and navigation

- Multi-screen display, wireless, easy to share

- Advanced 3D Measurement Software

- HD Resolution 1920 x 1200 pixels

- 4-way Articulation

- Durable & Replaceable Video Probes

- B series automotive borescope with CE&RoHS

- Optional diameter probe: 3.7mm, 4.5mm, 5.5mm, 6mm dual lens

- Flexible and Rigid inspection camera

- B+series portable industrial borescope with CE&RoHS

- Optional diameter probe: front view 2.2mm;2.8mm; side view 3.0mm.

- Flexible and Rigid inspection camera

- 5" Touchscreen Monitor

- Optional diameter probe: 1.2~8.4mm

- Tube socket design, easy to plug and unplug;

- Portable M-series industrial endoscope, easy to use.

- Articulating Videoscope with mechanical articulation for 360º.

- Interchangeable tubes with the same main body.

- N-series Digital Borescope has the latest intelligent platform with advanced image processing ability.

- Articulating borescope with electric rocker controlling system

- More friendly user interface, intuitive and easy to use.

An endoscope is a type of precision instrument. The first part of the industrial endoscope is a display monitor, and the second part of the industrial endoscope is a flexible insertion tube. What calls special attention is that the line consists of two essential parts: an optical lens and a micro-camera sensor. The best endoscope camera is widely applied in aviation, ship, chemical, engine, power, boiler, automotive industry etc.

As we all know, the above industries are high-tech industries. These industries require sophisticated testing equipment, such as best endoscope camera. The videoscope can go deep into the instrument and check it.The industrial borescope replaced our eyes. It solves many problems due to limited space. With the development of the economy, there will be more and more industrial endoscope demands for various precision instruments. The role of the video endoscope will be irreplaceable.

An industrial endoscope camera is used to observe walls, pipes and the inside of the engine. The industrial endoscope inspection is carried out in the maintenance and repair of automobiles. The flexible endoscope is also applied to HVAC, pipes and machinery. The industrial borescope camera has one huge advantage. It doesn’t damage the drains, sewer pipes and heating vents when the pipe inspection camera checks the instrument.

The industrial endoscope can perform non-destructive inspections on hard-to-reach places. The rigid endoscope can go in and inspect a lot of areas, including air ducts, furnaces, motors, pistons, gears, valves, compressors, boilers and condenser tubes. Thanks to the industrial endoscope and lightweight enclosures, the videoscope camera is very flexible and mobile. An industrial borescope inspection camera can help you locate potential problems quickly and easily. You can run the digital inspection camera without having to disassemble the system or machine. The automotive borescope allows corrective actions to be taken before costly downtime.

Yateks has nearly 20 years of experience in the industrial endoscope. We have a complete set of endoscope definition R&D, production and sales systems.

There are many types of industrial borescope, no matter which industry you need for testing. Our video endoscope has served customers all over the world. Our industrial videoscope has passed the inspection of authoritative organizations in European and American countries. Industrial endoscope refers to your trust.

If the video endoscope you purchased has some problems within a year, we are responsible for maintaining the industrial endoscope. We don't charge anything except the cost of materials and labour. We will start to repair the industrial borescope as soon as we receive the industrial videoscope you send us. We promise to deliver an improved industrial videoscope to you within a month.

The role of the industrial endoscope in car repair is also significant. The first thing we must know is that automobile inspection and maintenance is very professional and meticulous work. The use of the industrial endoscope for car maintenance also solves a big problem. We know that the entire automobile system is composed of many parts. When there is a problem with our car, we will go to the repair shop to repair the vehicle. Some car parts are broken, and we can see with our eyes. But some internal parts are invisible to us. Unless all these parts are removed or we use an industrial endoscope, we cannot repair the car. However, dismantling the interior of the vehicle requires a lot of time. The damage to the car is irreversible. Even if the car engine is disassembled, the problem may not be discovered for the first time.

Fortunately, thanks to the industrial endoscope, the emergence of the automotive borescope solved this problem. Firstly, let's briefly introduce the car endoscope. We all know that, as a whole, an automotive borescope consists of two parts. One part of the industrial endoscope is a display and operation panel, and the other part of the industrial endoscope is a detection tube with a camera. If there is a problem with the car engine, solving the industrial endoscope problem becomes very easy. The first thing we should do is to open the hood. We were finding the port where the tube of the industrial endoscope can enter. The following is operating the panel and letting the automotive borescope slowly enter the car's interior. We use the monitor to find the problem. In this way, we can save a lot of money for the car owner, and the issues can be found quickly.

With the development of communication technology, 5G has entered people's work and life. If the mobile phone and the industrial videoscope can be connected, many problems will be solved. In which case do I need to join the videoscope with a mobile phone? One situation is when multiple people share test results. Another concern is when professional maintenance personnel are not on site. When the on-site personnel cannot solve the inspection results, remote guidance becomes very important. As long as you have a mobile phone with 3G or 4G and can access the Internet via wireless or mobile data, the problem becomes much more straightforward. Next, you need to download a specified APP on your phone. When your phone is connected to the Internet, you can view the test results in real-time on the screen by opening the APP.

- The endoscope camera is made of 316 stainless steel material. The working environment of the probe of the endoscope is very corrosive. The anti-pollution and anti-corrosion ability of available materials is inferior, resulting in the endoscope's short service life. The material we use to be more wear-resistant and IP67 rated.

- The UltravioletIndustrial Borescope is suitable for the detection of explosive materials which belongs to fluorescent reactants. Using the principle of fluorescence reaction, we can find problems that are not found under white light.

- Our 3D Measurement Industrial Video Endoscope can not only detect defects but also accurately measure weaknesses. After getting the size data of the fault, we can specify a specific repair plan.

- Yateks Automotive Borescope has a temperature control sensor protection system. When the detected temperature exceeds 75 ℃, the power supply of the engine borescope will be automatically disconnected.