-

The principle of online monitoring system

The online oil monitor is a device used to monitor the state and performance of oil in mechanical equipment or systems. It provides information on oil quality, contamination levels, wear and equipment health by detecting and analyzing the physical, chemical and electrical properties of the oil in real time.

The following is the general working principle of the online oil monitor:

- Sensor collection Oil online monitors are usually equipped with a variety of sensors for collecting various parameters in the oil. These sensors can monitor oil temperature, viscosity, turbidity, acid value, base value, moisture content, particulate matter and other important indicators.

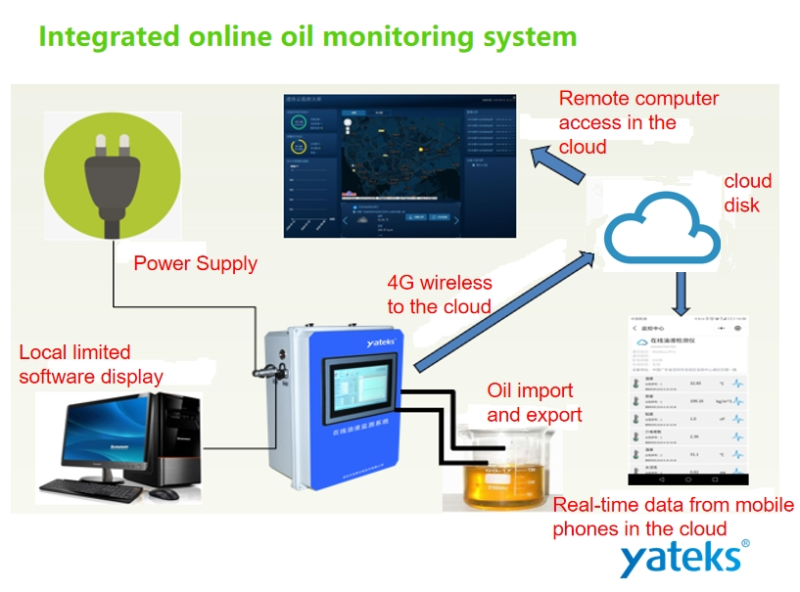

- Data transmission The sensor transmits the collected data to the central processing unit of the monitoring instrument through cable or wireless communication. Data transmission can be real-time, periodic or intermittent, depending on the configuration and requirements of the monitoring system.

- Data processing and analysis The central processing unit receives the data collected by the sensor, and performs data processing and analysis. It will filter, calibrate and scale the data to ensure the accuracy and reliability of the data.

- Health assessment By comparing and analyzing the collected data, the online oil monitor can evaluate the health status of the oil and its compatibility with the equipment. It can detect the degree of contamination of the oil, changes in pH, moisture content, size and quantity of particulate matter, etc., so as to judge the degree of wear and health of the equipment.

- Alarm and notification If some parameters of the oil exceed the set threshold or reach the warning level, the online oil monitor will trigger the alarm system to remind the operator to take corresponding actions through sound, light or remote notification. handling and maintenance.

By continuously monitoring and analyzing the condition of oil, oil monitors can provide vital data and information to help predict equipment failure, extend equipment life, optimize maintenance schedules, and minimize equipment failure and downtime.

-

What is the technology of evaluating the working condition of the machine and predicting the failure and determining the cause, type and parts of the failure

The technology of evaluating the working condition of the machine and predicting the failure and determining the cause, type and parts of the failure is usually called machine fault diagnosis and fault prediction technology. These technologies are designed to detect potential failures in advance and identify the cause, type and affected parts of the failure by monitoring, analyzing and interpreting the condition and performance of the machine.

The following are common techniques for evaluating machine condition and predicting failure:

- Vibration analysis By monitoring and analyzing machine vibration signals, the working condition of the machine can be evaluated and potential failures can be detected. Vibration analysis can help identify problems such as wear, imbalance, and looseness of mechanical parts.

- Temperature monitoring Monitoring the temperature changes of different parts of the machine can help detect overheating, poor cooling and other fault conditions, and determine the possible cause of the fault.

- Oil analysis By analyzing the chemical composition and physical characteristics of the lubricating oil or hydraulic oil used in machines, the quality, degree of contamination and wear of the oil can be evaluated, thereby predicting equipment failures and determining the causes of failures.

- Sound analysis By monitoring and analyzing the sound signals generated by the machine, abnormal noise or vibration can be identified, and then the potential failure type and cause can be deduced.

- Image recognition Using computer vision technology to analyze and compare machine images, it can detect wear, cracks, deformation and other problems on the machine surface, and provide information about the type and cause of the failure.

- Data mining and machine learning By collecting and analyzing machine operation data and applying data mining and machine learning algorithms, models can be built to predict failures and identify causes of failures. These algorithms can discover patterns and trends in the data, thereby providing the ability of failure prediction and diagnosis.

The comprehensive application of these technologies can help enterprises realize intelligent monitoring and maintenance of equipment, improve equipment reliability and operating efficiency, and reduce maintenance costs and downtime.

Function of online oil monitor: This system is an equipment lubrication monitoring product based on sensing technology, which can monitor and evaluate data online at the same time, early warning of equipment failure risk, prevent equipment failure, and prolong equipment life. The monitoring parameters include: viscosity, moisture, oil quality, wear particles, pollution degree (cleanliness), temperature, density, vibration, leakage and other parameters.