Oil particle size testing is an important technique used to assess the level of particle contamination in lubricating oils. Particulate contamination has a direct impact on equipment wear and risk of failure, so accurate measurement and monitoring of particle size and concentration in oil is critical. Particle size detection technology uses sophisticated instruments and methods to accurately count, distribute and shape particles in oil. This kind of detection can help users understand the cleanliness of oil in time, formulate corresponding maintenance measures, and improve equipment reliability and life. Oil particle size detection has important application value in industry, automobile and other fields, and is an important tool for preventive maintenance and equipment maintenance.

Detection method and precautions of oil particle size

There are many methods to detect the particle size of oil, common methods include centrifugal sedimentation method, filtration method, optical microscope method and laser particle size analysis method, etc. The following is a brief introduction to these methods and caveats:

-

Centrifugal sedimentation method:

The oil sample to be tested is centrifuged to make the particles settle down under the action of centrifugal force.

During the sedimentation process, the particles will be distributed in the centrifuge tube according to their size. By observing the scale on the centrifuge tube, the size range of the particles can be estimated.

Note: It is necessary to ensure the stability of the centrifugation conditions and the accuracy of the scale, and avoid external vibration interference during operation.

Filtration method:

Pass the oil sample to be tested through filter media such as filter paper or filter membrane, and the particles will be trapped on the filter media.

Use a microscope to observe the particles on the filter media, and estimate the particle size distribution of the particles based on the number and size of the particles.

Matters needing attention: choose the appropriate filter medium and appropriate filter speed to avoid particles clogging the filter medium.

-

Optical microscopy:

Use a light microscope to observe the particles in the oil sample.

Estimate the size distribution of particles by measuring the size and number of particles.

Note: It is necessary to use a high-quality microscope and an appropriate magnification to ensure the accuracy of observation and measurement.

-

Laser particle size analysis method:

Using a laser particle size analyzer, the size and distribution of particles are analyzed through laser beams and scattered light signals.

The instrument will measure the scattered light intensity of the particles at different angles, and calculate the particle size range and distribution of the particles according to the characteristics of the scattered light.

Precautions: Correctly operate and calibrate the instrument to avoid external interference and sample contamination.

When testing the particle size of oil, you need to pay attention to the following items:

Choose an appropriate detection method, and select a suitable detection method according to actual needs and sample characteristics.

According to the requirements of the detection method, prepare samples and reagents, and ensure the representativeness of the samples.

Strictly follow the operating instructions to avoid errors and pollution during operation.

Pay attention to the calibration and maintenance of the instrument to ensure the accuracy and reliability of the measurement results.

For key application fields such as lubricating oil, pay attention to the cleanliness of the testing environment and maintain the integrity of the sample.

Combined with other relevant parameters, such as particle size distribution, particle shape, etc., to comprehensively evaluate the quality and performance of oil products.

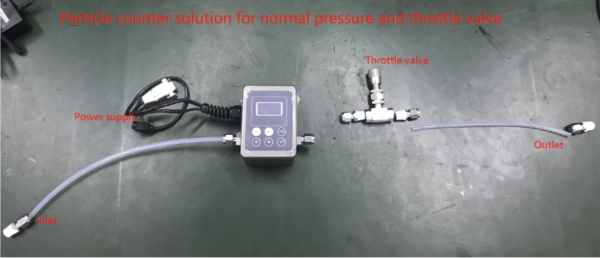

Yateks provides you with oil particle size monitoring system solutions. If you are interested in the product, please contact us to send you product information and quotation.