An Aircraft Maintenance Engineer’s fundamental purpose is to ensure aircraft are safe and airworthy to fly. No aircraft takes off without being certified to do so by an engineer – it’s one of the most crucial roles when it comes to safety in the aviation industry.

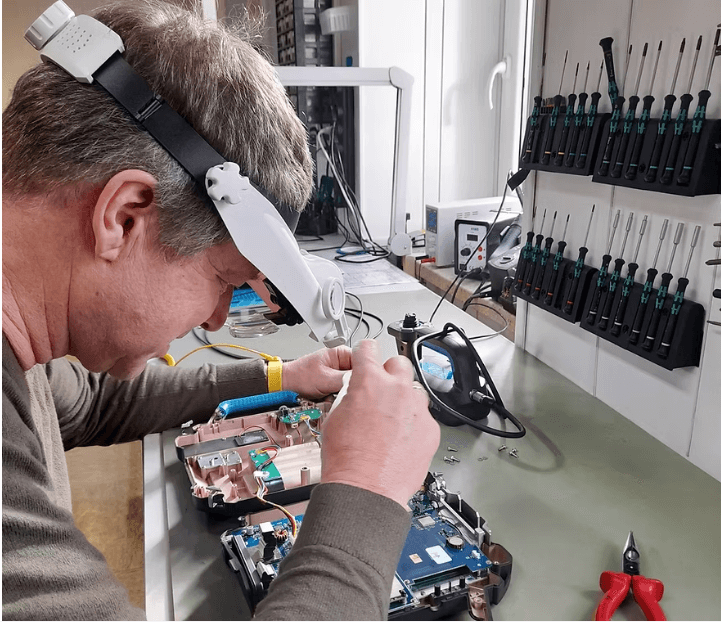

Without eyes inside engine components, maintenance technicians are flying blind. Technicians must be able to detect cracks, buildup, corrosion, and damaged pistons in order to successfully conduct a thorough inspection.

An Aviation Borescope is also useful to inspect brakes, inside wings and behind instrument panels. Having a state-of-the-art borescope on hand means less time spent disassembling and reassembling key pieces of equipment. Resulting in quick non-destructive testing and inspection of hard-to-reach spaces to make informed maintenance decisions.

What are the benefits of a Yateks Borescope?

Yateks Portable borescopes are equipped with rechargeable batteries for on-the-go inspections and many offer both a microphone for live verbal notations during the inspection process as well as a removable SD card to store image and video recordings. Technicians can quickly and easily set up their equipment, perform and document inspection duties, and get back on to the next job fast.

Videoscopes – Combining the optical clarity of rigid borescopes with the flexibility of fiberscopes, videoscopes incorporate small video cameras. These video cameras provide high-quality visuals and allow users to record images for later review. Videoscopes use borescope software that may need regular updates.

Choosing the Right Borescope for Aviation Requirements

(1)Flexibility – If all you need is access to a straight-line area, then a rigid borescope can give you clear imagery without the increased cost of increased flexibility.

(2)Image Quality – If you need to be able to identify small details, opt for a borescope with clearer, higher-definition images. Improved resolution, adjustable lighting, and zoom functionality will all have an impact on the final image detail.

(3)Probe Length and Diameter – You need your borescope to be able to reach the components you’re inspecting. When in doubt, err on the side of caution; you’re better off having too much length than too little. You also need to be aware of the diameter of the space the probe must fit through. The borescope will need to pass easily through the narrowest diameter of the inspection space, so a thinner probe may be preferable.