By looking at the detection indicators of the oil analysis report, we can see a lot of information about the running state of the machine. The oil in a machine is often compared to the blood of a human body. Blood can provide many benefits to human body, including delivering oxygen and nutrients to tissues, carrying antibodies and heating/cooling the body. Oil also has many functions, including reducing friction, controlling temperature, providing additives and helping to control and remove pollutants.

When the machine When there is a problem, the fault symptoms usually appear in the oil. In the medical field, we use blood samples to monitor our physical condition. In industry, we use oil. Oil analysis can predict the impending failure, and it is a normative tool, which can be used to guide the decision-making on the selection and application of lubricating oil, oil replacement interval, storage and treatment practice and pollution control strategy.

-

Elemental analysis All oil analysis reports first list 20 to 30 elements.

Their range includes common metals commonly found in oil-wetted parts, such as iron, lead, tin and copper; Additive elements existing in some types of oils, such as zinc, calcium and phosphorus; Common pollutants, such as silicon (dirt) and sodium (coolant or seawater). Like all oil analysis tests, the results of elemental analysis should change with time.

Although elemental analysis is the foundation, it should be used with caution, because the analysis program has limitations that affect the results. Perhaps the important limitation is the particle size. Most modern laboratories use inductively coupled plasma (ICP) spectrometer to report elements. This method cannot measure particles larger than 3 microns. Therefore, large particle contamination or wear patterns (such as adhesive wear) may not be accurately reported by ICP. In fact, it is entirely possible for the gearbox to experience severe abrasion, but ICP reports little or no iron or other worn metals.

Evaluating the information in the oil analysis report, such as viscosity, worn metal, particle count and water pollution, will help to fully understand the conditions that affect the operation of the machine.

-

Quantitative indicators of wear particles

In gearbox and other assets, common failure modes will lead to large (> 5 microns) wear particles. With these assets, particle quantifier (PQ) testing should become routine. This test uses the magnetic Hall effect to determine the concentration of ferromagnetic particles in the sample, regardless of their size. With the passage of time, understanding the trend of petroleum PQ index can provide valuable information about the initial failure. Other tests, such as direct reading ferrography, can also measure large wear particles. However, PQ testing has become an industry standard because of its relatively simple and low cost. Please note that PQ testing cannot detect wear of nonferrous metals or nonmagnetic forms of iron, such as rust particles.

-

Viscosity

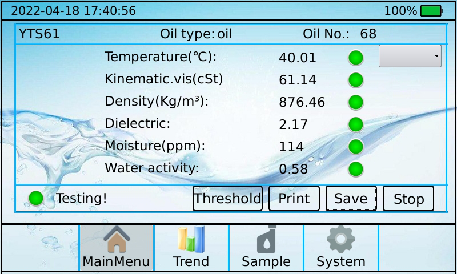

Viscosity is an important characteristic of any lubricating oil, so it is meaningful to measure the viscosity of oil as part of any conventional oil analysis. The viscosity of industrial oil is usually reported at 104 F (40 C), and the viscosity of automobile grade oil is usually reported at 212 F (100 C), although the measurement effect is better at these two temperatures.

Through these two figures, the viscosity index or the rate of change with temperature of the oil can be calculated.

In engine oil samples, viscosity can help to determine whether the oil is still within the grade range, and it is a good indicator of fuel dilution. In industrial fluids, viscosity testing is not very useful. The change rate of industrial oil viscosity with time is far from obvious. Usually, the viscosity will not change until the remaining life of oil is less than 10%; Long after sludge, varnish and other deposits begin to form. The viscosity test of industrial fluids is actually to ensure that the correct oil grade is used and there is no cross-contamination.

-

PH value

Acid value and alkali value tests are sometimes collectively referred to as neutralization values, which are used to measure the acidity or alkalinity of samples. Acid value (AN) measures the accumulation of acid by-products. It is usually associated with oxidative decay. Therefore, it is an index that can be used to measure the health of oil products. In engine applications, especially natural gas engines, the AN of oil can also be used to measure the presence of acidic combustion by product.

The radix (BN) is almost exclusively used for engine oil analysis. This test measures the content of overbased detergent additives in oil. Although it has been used to measure the health status of additives in history to promote condition-based engine oil replacement, with the adoption of low-sulfur and ultra-low-sulfur fuels, the importance of BN testing has gradually decreased. AN and BN tests need a representative new oil reference for comparison.

-

Moisture

Moisture is a potential pollutant, which will lead to rust and corrosion and change the thickness of oil film. Therefore, it is an important consideration to detect the moisture in the oil sample and control the moisture entry.

There are many kinds of water testing techniques, ranging from simple hot plate testing, which is often called “crack testing”, to complex methods such as Karl Fischer (KF) analysis. Because oil is hygroscopic, all samples will show some water pollution. The key is to measure and control the water level below the saturation point at all oil temperatures in use. In fact, this means that the content of turbine oil is less than 100 ppm, the content of hydraulic oil and other oil products containing AW additives is less than 150 ppm, and the content of gear oil is less than 250 ppm.

Because of these relatively low detection limits, the reliable test method is KF method. For very low level and/or very accurate results, the co-distillation method of KF test should be used to avoid additional interference.

According to the specific application, most lubrication experts realize that 50% to 80% of lubrication-related problems are directly or indirectly caused by particle pollution. Therefore, oil wear monitoring should be the routine operation of all samples, except perhaps starting oil samples. The test report shall count particles in three size ranges according to ISO 4406 reporting standard: > 4 microns, > 6 microns and > 14 microns.

In addition to vibration analysis, thermal imaging and ultrasonic testing, in-use oil analysis is also an integral part of active condition monitoring strategy.

As with any test measurement, the quality of diagnosis depends on the data. Related products: Oil metal wear sensor, oil metal wear sensor, non-contact abrasive particle sensor, adsorption abrasive particle sensor. Yateks provides a variety of oil analysis equipment. If you have any requirements, you can contact us at any time.