With the rapid development of wind power generation technology, the application of industrial borescopes in wind power has become increasingly important. Industrial borescopes play a key inspection and maintenance role in wind power to ensure the reliability and efficiency of wind power generation equipment.

Which parts of the wind turbine will fail?

1.Blade Inspection

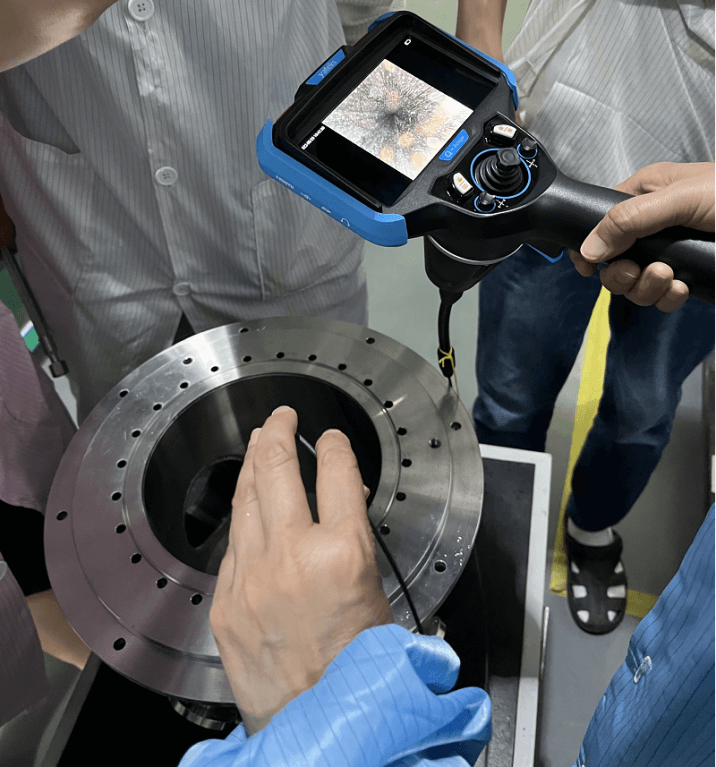

The blade of a wind turbine is one of its core components, which directly affects power generation efficiency and safe operation. The use of industrial endoscopes allows for visual inspection of the inside of the blades to find and assess problems such as defects, cracks, wear and tear, and foreign objects on the surface of the blades. Through the inspection data, the operation and maintenance personnel can take timely repair measures to ensure the normal operation and prolong the service life of the blades.

2.Generator Inspection

The generator of wind turbine is the key energy conversion equipment, which needs to be kept in good working condition. Industrial endoscope can be used for visual inspection inside the generator to check the status and operation of the rotor, winding, cooling system and other components. Through the application of endoscope, potential faults, damages or wear problems can be found in advance, and timely repair and maintenance measures can be taken to ensure the stable operation of the generator.

3.Gearbox Inspection

Gearbox is one of the core components of wind turbine, and its internal gears, bearings and lubrication system need to be regularly tested and maintained. Industrial endoscope can enter into the gearbox to observe the wear degree of gears, the state of bearings and the working condition of lubrication system, so as to find the abnormality in time and take corresponding repair and maintenance measures.

4.Bearing Inspection

The bearing of wind turbine carries the weight and rotational force of the rotor and is a key running part. Industrial endoscope can be used for bearing inspection, including observing the lubrication condition, wear and vibration of bearings. Through regular inspection, abnormal conditions of bearings can be found in time to prevent failure and damage and ensure the normal operation of wind turbines.

5.Tower inspection

The tower of wind turbine is an important structure to support and protect other parts. The use of industrial endoscopes can detect the inside of the tower barrel and find possible corrosion, cracks, deformation and other problems. Such an inspection can detect structural abnormalities at an early stage and take corresponding repair and reinforcement measures to ensure the safety and stability of the tower.

6.Pitch mechanism detection

The pitch mechanism is a key component for controlling the blade angle in wind turbines. Through the application of industrial endoscope, the internal transmission system and hydraulic system of the pitch mechanism can be inspected to ensure its normal operation and reliability. At the same time, it can also check the hydraulic pipelines, connectors and sealing devices, etc. to prevent leakage and failure.

7.Tower base inspection

The tower base of a wind turbine carries the weight and wind pressure of the entire unit, so its structural integrity and stability are critical. Industrial endoscopes can be used to inspect the inside of the tower base, observing cracks in the concrete, corrosion of the steel reinforcement and other structural problems. Through timely detection and assessment of these defects, appropriate repair and reinforcement measures can be taken to ensure the safety and stability of the tower base.

8.Generator Inspection

The generator of a wind turbine is one of the core components, responsible for converting wind energy into electricity. Industrial endoscopes can be used to inspect the inside of the generator, including observing the insulation condition of the windings, checking the wear and tear of the bearings, and assessing the balance of the rotating parts. Through regular generator inspection, potential faults can be found and repaired in time to ensure the efficient operation and reliability of the generator.

9.Cooling System Inspection

The cooling system of a wind turbine is responsible for dissipating heat and keeping the temperature of key components within a safe range. Industrial endoscopes can be used for cooling system inspection, including observing the connection status of cooling pipelines, the working effect of radiators and leakage. Through regular inspection, problems such as blockage, leakage or damage in the cooling system can be found and repaired in time to ensure the normal heat dissipation and operation of the generator set.

The application of industrial endoscopy in wind power provides convenience and efficiency for the inspection and maintenance of wind power generation equipment. It can visually inspect the interior without disassembling or damaging the equipment, discover potential problems and take corresponding measures. Through the application of industrial endoscope, the operation and maintenance personnel of wind power generation equipment can find and solve problems in time to ensure the normal operation and reliability of the equipment.

what are the advantages of industrial borescope in wind power detection?

-

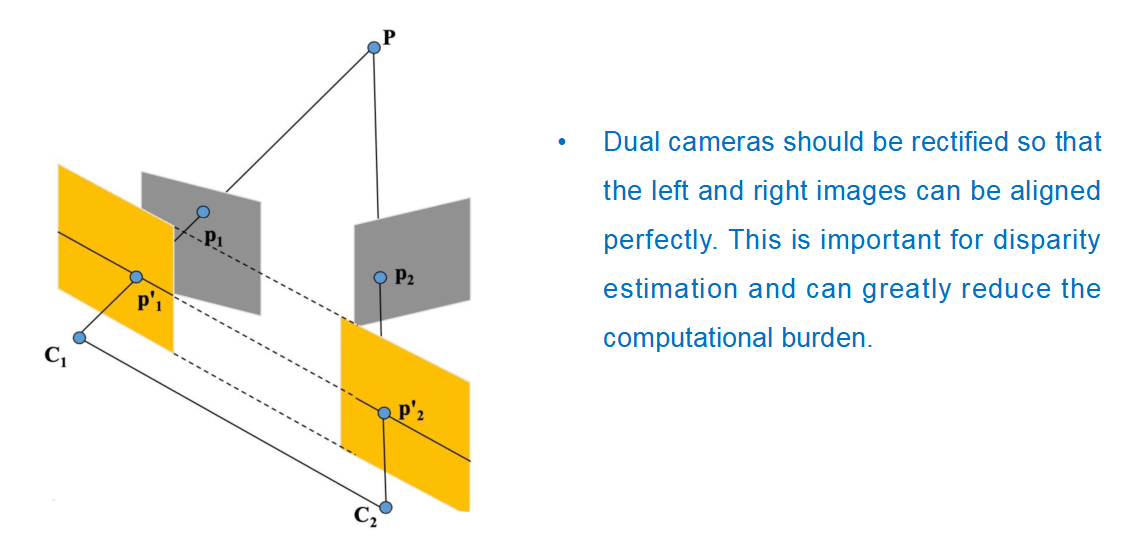

High-definition imaging

Industrial endoscopes are equipped with high-definition imaging technology, which can provide clear, detailed images. This enables inspectors to accurately observe and assess the internal condition of the equipment and identify potential problems.

-

Bending Guidance Capability

The insertion tube of the industrial endoscope has a bending guiding ability that allows it to easily enter narrow and complex spaces, enabling inspection of hard-to-reach areas. This allows all parts of the wind turbine to be thoroughly inspected, ensuring that problems are not overlooked.

-

Durable Performance

The design and material selection of the industrial borescope has good durability performance, which can adapt to the harsh working environment and frequent use. This ensures the reliability and stability of the endoscope during long-term use.

-

Flexible application

The industrial borescope can choose different probes and accessories according to specific needs to meet the inspection requirements of different wind power generation equipment. This flexibility makes it suitable for various types and sizes of wind power generation equipment.

The application of industrial borescopes in the wind power field provides an efficient, accurate and non-destructive method for the inspection and maintenance of wind power generation equipment. Through its unique structure, working principle and technical features, industrial endoscopes can help the wind power industry identify and solve problems in a timely manner, improve equipment reliability and operational efficiency, and promote the sustainable development of the wind power industry.