1.What is Oil monitoring?

Equipment lubricant and abrasive wear monitor ( refer to Oil monitoring) is the important and basic work for equipment lubrication management and repair. It is the main method to improve equipment reliable and ensure the equipment running safety.

Oil monitoring technology is according to regular monitor the lubricant physical and chemical performance. wear metal and contaminant particles. Knowing the equipment lubricating and wearing state to diagnose the abrasive wear type, position and cause. Providing the scientific basis of equipment repair and guiding company equipment state repair and lubricating management. to prevent the equipment major accident and decrease the repair cost.

Statistical information of equipment fault:

80% equipment fault caused by lubricant wearing;

70% diesel fault caused by oil pollution, 50% of them caused by wearing;

40% rolling contact bearing lose efficacy and fault caused by lubricating system;

51% gear fault caused by bad lubricant and inordinate wear.

70% hydraulic system fault caused by hydraulic medium heavily polluted;

Friction wearing consumption proportion 1/3~2/3 in total energy consumption.

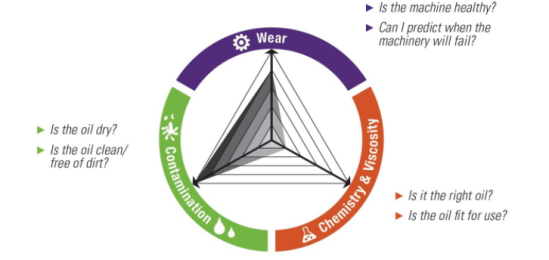

What is the use of oil monitoring?

Lubrication state evaluate:

According to regular monitor equipment lubricant. to find the cause of lubricant degradation and pollution. to provide available lubricating mode and change oil period;

Wearing fault diagnosis:

According to analyze the wearing metal particles of equipment used oil. to forecast the fault situation of equipment main friction pair and diagnosis the position. cause and situation of breakdown, then it could repaired depends.

What benefits can oil monitoring bring to company?

1. Advancing the equipment more reliable, to avoid equipment major accident:

According to apply multi professional monitoring medium to constantly monitor the equipment oil. to prevent the major accident occurs and advance the equipment reliable.

2. Saving repair cost and guide to repair depends on situation :

Repair after breakdown—-Is it happening in your company equipment?

Prevention and maintenance—-it is easy to over maintenance, 1/3 repair cost still waste.

Forecast and maintenance—–repair depends on the forecast fault, decrease the repair cost.

Proactive and maintenance—-advanced maintenance idea, decrease a lot of company total repair cost.

3.Increasing equipment lifespan, creative greater production value.

Equipment is the foundation of company survival and development. it could advanced and increased its lifespan by professional oil monitoring.

Benefits forecast by oil monitoring:

Based on the information which statistics from inner and overseas, The company which carry out the equipment condition maintenance, their equipment repair cost decreased 30% to 40% , equipment accident decreased 40% to 60%. According carry out oil monitoring, you could get the following benefits:

- Following up and monitoring the wearing state and changing trend of equipment. Providing the scientific basis for equipment management operator make machine halt maintenance plan and extensive maintenance plan. Achieving the equipmentcondition maintenance, could detect and repair the hidden fault in time, and extend the period of extensive maintenance, to gain economic profit.

- Becauseof carrying out the wearing situation monitoring, find out the equipment unusual wearing and hidden fault, guide the equipment conditional maintenance, the company could avoid major equipment accident occur and reduce the maintenance

- By carrying out oil monitoring regularly, companycould find and eliminate the lubricating hidden fault of the equipment. By achieving the equipment conditional oil exchange ,and extending the period of oil exchange, the oil cost reduced, then company gain the profit.

- By carrying out oil monitoring equipment conditional maintenance, theequipment could be advanced more reliable and was reduced accident halt, then gain the economic benefit and social benefit.

Yateks, the professional manufacturer and experienced solution provider ofoil analysis products for around 20 years.