According to domestic and foreign statistics, about 70% of hydraulic system failures are caused by oil pollution. Solid particulates are the most common and harmful pollutants in hydraulic and lubrication systems. By detecting the oil particle content in the oil, it can not only improve the reliability of the system and prolong the life of the system. It can also reduce the accident rate and improve production efficiency. Use the oil contamination sensor to detect the particle content in the oil in time to help the staff correctly analyze the oil contamination in the hydraulic system. Judge the working condition of mechanical parts.

Contamination sensors are used to detect the size and number of solid particles in liquids. It is mainly used in aerospace, electric power, petroleum, transportation, machinery and other fields. It can perform solid particle contamination detection on the following oils. Hydraulic oil, lubricating oil, transformer oil, turbine oil, gear oil, engine oil, etc.

What are the technical highlights of the pollution sensor?

-

High precision

Using shading method, the minimum detection rate is 1um;

-

Fast

Real-time response, automatic reading of flow rate, adaptive working conditions;

-

High channel

Built-in 8-channel detection segmented display pollution level;

-

Wide coverage

Covering testing standards such as GB/ISO/NAS/GJB;

-

High adaptability

Two detection modes are adjustable;

Below are the main technical specifications of YFJ-4 online particle counter sensor for your look, of course if you are interested and want to learn more information and application, please feel free to contact.

- Light Source: semiconductor laser

- Eight Channels and testing range:1~100μm or 4~70μm(c)

- Sensitivity:1μm(ISO4402) or 4μm(C) (ISO11171,GB/T18854-2002)

- Standards: NAS1638, ISO4406, SAE749D, ГОСТ17216, AS4059D, etc.

- Accuracy: ±0.5 pollution level

- Online pressure: 0.2~10MPa;0~40MPa(equip with pressure reducing valve)

- Online flow: 50~300mL/min

- Oil temperature: 0-80℃

- Power supply: DC9V, 1000mA

- Size: Length: 100mm×Width:75mm×Height: 71mm

- Output: RS485

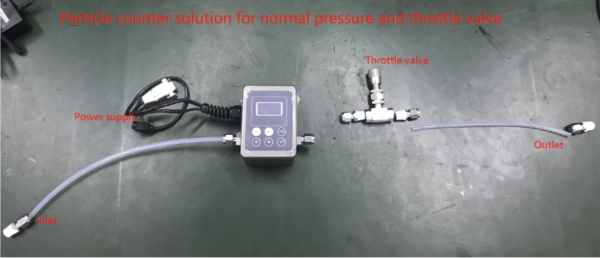

Below are the pictures of this sensor and solution we provided for customers for your reference.