Lubrication, as an essential part of big mechanical equipment, is just like the blood of human body which contains much health information of equipment. Taking oil samples from the equipment body for analysis is a key step to diagnose where the equipment is ill. Among all analysis methods, ferrography analysis is one of the most frequently used technology. What can realize successful ferrography making and analysis? There are five elements to be shared.

Reliable ferrography. The task of ferrography is to get oil wear debris regularly deposit on the ferrorgaphy slides. In aspect of principles, there are mainly two types of ferrographies on the global market. One is the thistle tube ferrography, another one is the ferrography with peristaltic pump.

- For thistle tube ferrography, the oil samples and wear debris flow through the thistle tube under their own weight. How to ensure that they deposit on the slides very evenly? The secret is the processing accuracy of the thistle tube. Only with a high accuracy thistle tube shape can it ensure the key step of depositing evenly.

- For ferrography with peristalticpump, the oil samples are extracted to delivery tube by a micro-pump and then averagely deposit on the slides. The key point is the high performance of the micro-pump to ensure enough mixing of oil samples and stable flow velocity. Without an excellent micro-pump, it’s very difficult to make successful ferrography slides for later analysis.

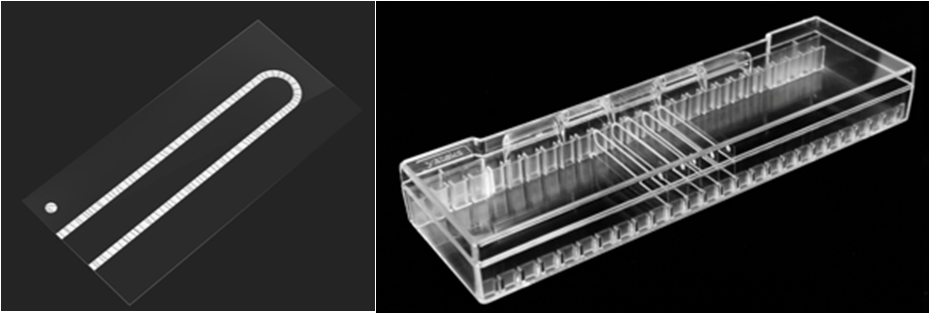

Reliable ferrography slides. Ferrography slides, as the most frequently used consumables, must be made to be clean and reliable. There are also several key points for this small item:

- The U barrier size, thickness and width need to be good and reliable enough to block the oil samples from breaching over the barrier. To ensure these points, a highly accurate automatic dispenser and an experienced technician is very important.

- It makes things easier if the user can know which side is the positive side, or the user has to touch the U shape and get it polluted. A white dot marker is necessary.

Applicable Ferroscope. When it refers to microscope to observe the micro structure of samples, there are very many options. However, to observe ferrography slides, it’s very necessary to choose the microscope which have two types of light – reflected light and transmission light. Only by analyzing the wear debris on the slides under different light and light filter can the analyst make more accurate evaluation in the analysis report.

Easy-to-use software with rich data base. The final aim of ferrography analysis is to generate a report of diagnosis and give technical advice. During this step, an easy-to-use software is very helpful to improve the efficiency. One one hand, the ferrography slide should not only be observed by microscope, but also should be displayed on a bigger screen. This would make it very convenient to do analysis. On the other hand, rich data base is very great for comparison and reference while the analyst makes the report. The bigger the data base is, the easier to make more accurate analysis.

Professional analyst with rich experience. It not enough to observe the slides and simply compare to have judgement. Besides the size, shape and arrangement form of wear debris on the ferrorgraphy slides, the color is also another quite important characteristic. Big mechanical equipment is composed of lots of different metal components and to know what the metal material is very helpful to position where the problem happens. However, sometimes it’s very difficult to draw a conclusion about the metal material, especially when the metal color may belong to several different metal material. In this case, the experienced analyst will usually heat the ferrography slides to a certain temperature when the wear debris may change to different color at different temperatures.

Yateks is a professional manufacturer of oil analysis instruments and methods. Over the years, we have served customers globally and have accumulated much experience. If you have any questions or interest in oil analysis or oil analysis instruments, you’re greatly welcomed to contact us at [email protected]. Our professional sales engineer would be happy to talk with you.