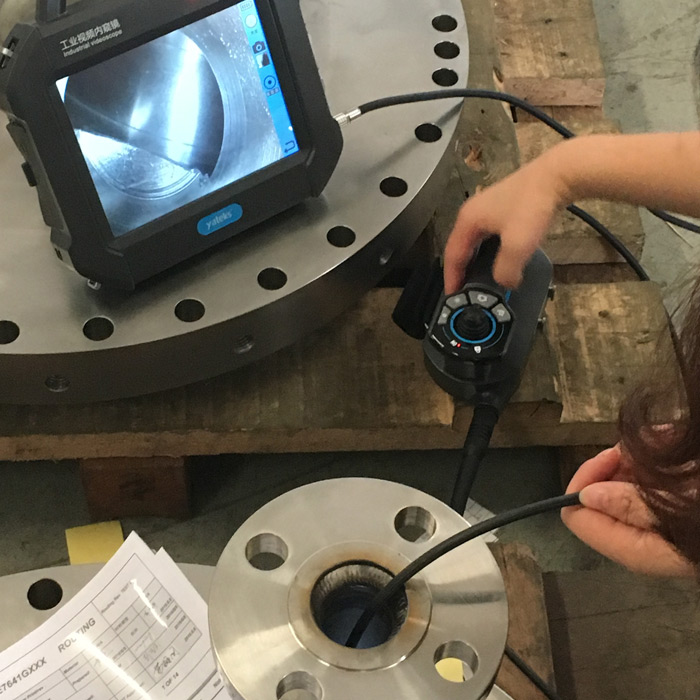

Remote Visual Inspection(RVI) with industrial endoscopes to better restore defects and make effective decisions.

Engine borescope inspection is a visual detecting method for quality control of areas that human eyes can not observe directly, special areas such as vessels, pipe inner part of the non-detachable equipment, the inner surface of narrow gap, liquid surface etc.

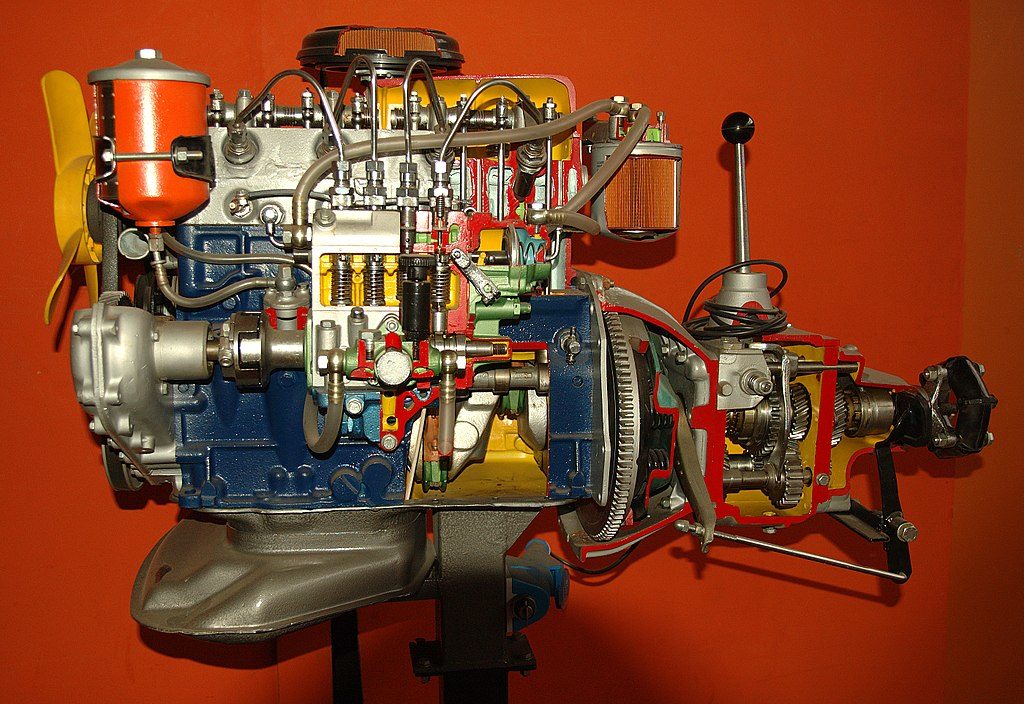

The marine diesel engine is the powerful heart of the ship and the most troublesome place in the ship mechanical system. Its safe and reliable operation is the basic guarantee for the safe operation of the ship. Due to the complicated structure of the diesel engine, the working conditions are bad, and with the increase of the strong load, The possibility of failure is extremely great. Once a failure occurs, it will not only affect the operation of the entire power unit, but also cause huge losses, and engine borescope inspection will endanger personal safety and cause serious consequences.

Industrial Borescope is widely used in various types of ships. Because their marine diesel engines work under severe working conditions such as strong impact, high temperature, high pressure, and high humidity, they are prone to failures and accidents. The faults are mainly classified into structural faults and performance faults. Structural failure. Mainly manifested in parts wear, cracks, improper assembly, friction between moving parts and components, and oil and gas circuit blockage; and performance failures, mainly in the performance of mechanical performance indicators, structural failures will reflect the performance of the machine And the assessment of performance indicators can also reflect the existence and severity of structural failures.

Difficulties in starting a diesel engine in a ship When there are faults in starting a fault, there are three cases:

(1) At the time of starting, the crankshaft does not move at all or the rotation is very slow, that is, the starting speed is too low.

(2) When starting, the starting speed is normal, but the marine diesel engine does not catch fire.

(3) At the time of starting, although the diesel engine of the ship was on fire, the diesel engine of the ship was not working properly, the speed was unstable, and even the fire was extinguished.

Diesel engine inspection checklist and Cause Analysis:

(1) Starting system: the gas pipeline leaks or the gas pipe is too long, the gas source pressure is insufficient, and the air compressor is damaged.

(2) Fuel system: the oil pressure low parking lever is not under the plate, the fuel tank valve is not open, the fuel tank is not oiled, the fuel tank position is too low, there is air in the fuel line, the diesel filter is too dirty, the overspeed parking device is not reset, the tooth The stuck bar is not in the refueling position, the injector is not atomized, the fuel injection pump does not pump oil or the injector does not spray oil.

(3) Intake and exhaust system: the air filter is fouled, the intercooler is fouled, the explosion-proof door valve is not opened, the timing of the gas distribution is incorrect, and the exhaust system is fouled.

(4) Combustion system: The compression pressure is insufficient, the clearance between the piston and the cylinder head is too large and too small, and the cylinder head extends too far and too small.

(5) External conditions: start with load, the temperature of the oil is too low, the viscosity is too large; the water temperature is too low, it freezes in the water pump; the diesel temperature is too low and the viscosity is too large.

(6) Internal conditions: the valve touches the piston or the cylinder has foreign matter; burns the tile, holds the shaft, and pulls the cylinder.

The customer situation description:

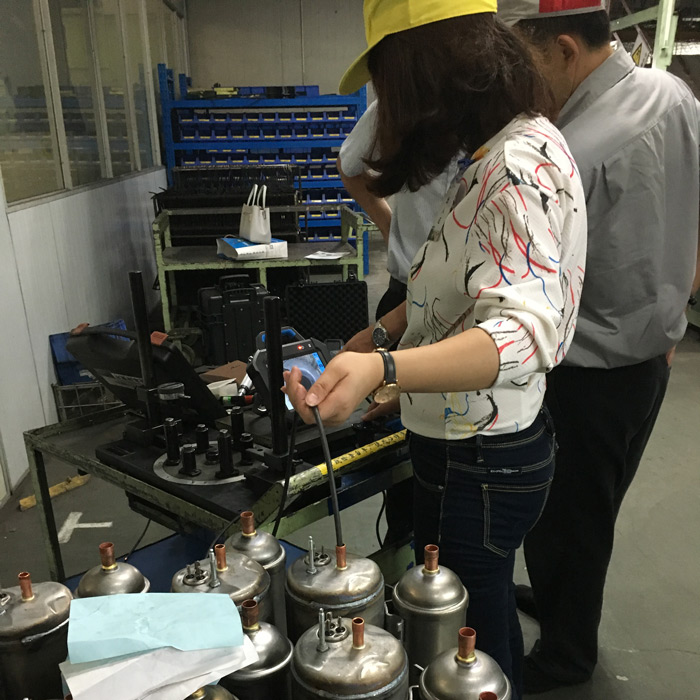

The customer company mainly deals with marine power system accessories. The main users of the endoscope check the corrosion, damage, and burrs of the deep oil holes and threaded holes on the diesel engine, piston and cylinder liner.

Demo results:

(1) The engine cylinder borescope can meet the needs of customers and can help customers find rust, damage, burrs, etc. inside deep oil holes and threaded holes;

(2) Customer requirements have been submitted to the Equipment Purchasing Department, and the purchase has contacted me for an official quotation;

Recommend: