Background of the project

The customer is a well-known automobile manufacturer. The customer uses the transmission oil of a lubricating oil company. The transmission moisture requirement is ≤1000ppm, because after the oil is mixed with water, it is added to the new car through filling equipment, causing dozens of There is a problem with the new car. The car is recalled, and the gearbox is cleaned and reassembled before it can be safely sold. As a result, it has caused great economic losses and brand impact.

During the communication between the two parties, the lubricating oil manufacturer emphasized that their oil products were produced in strict accordance with the standards; the automobile manufacturer analyzed the oil products through the oil laboratory instrument that the oil products were emulsified due to excessive moisture. Heavy rain, the air is relatively humid, and the moisture may enter through the breathing valve of the fuel tank.

Solutions provided by Yateks for customers

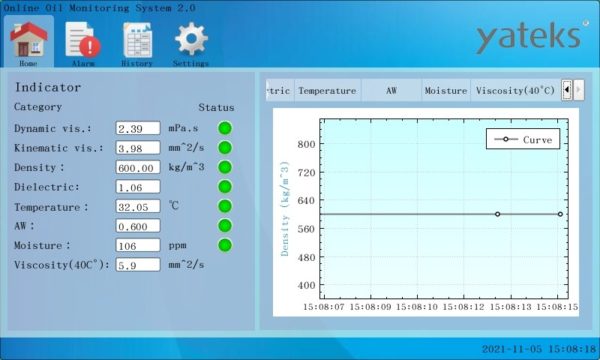

After the Yateks oil engineer communicated with the engineer of the customer’s relevant department, the customer decided to purchase the oil micro-water sensor, and then the customer would integrate it by himself. After communication, the customer finally accepted the solution of oil micro water sensor + industrial flat panel. And the sensor is calibrated according to the requirements provided by the customer. LCD screen 7-inch (16:9) industrial tablet computer, the client requires that the interface of the industrial tablet needs to enter a password before entering the interface; the alarm output point of the industrial tablet computer relay is connected to a speaker to increase the sound of the alarm; the signal line needs to be 20 meters; configure the oil tank to install the oil micro-water sensor.

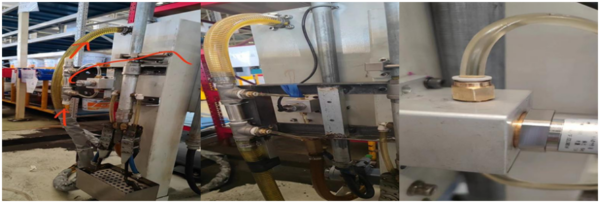

On-site installation

The oil is at room temperature and pressure, and there will be a little vibration on site. According to the parameters provided by the customer, the recommended installation is as follows

The customer’s feedback after using it is good. In the process of cooperation between the two parties, the customer’s brake oil online monitoring project also has opportunities for cooperation. During the use process, the pressure is 20Mpa. Because of the water entering, it will cause bubbles at 100-200℃. As a result, the brakes fail, and they will study this project as a topic. The water absorption capacity of the brake oil is very strong. The normal condition is 40,000 kilometers. It must be changed. The lubricating oil of the pressure pump is not large (about 100L), but the oil is relatively expensive. Change the oil every two weeks. Regardless of the quality of the oil, the oil should be changed regularly. An online oil monitoring device can be configured through communication.

Yateks, a national high-tech enterprise and a well-known brand in Shenzhen, has more than 10 years of experience in the research and development and production of industrial endoscopes and oil analyzers, and is a cooperative supplier of well-known enterprises at home and abroad. If you have any needs, please contact us.