With the vigorous development of the wind power industry in recent years, the cumulative installed capacity has also increased exponentially, and the maintenance cost of the gearbox part, which is a very important part of the entire set of equipment, is very high. Therefore, it is very important to judge the wear condition of the gearbox components through effective online monitoring, and the status analysis of the lubricating oil of the gearbox can play a key role by online monitoring.

-

Classification and cause analysis of gear faults

During the working process of the gear box, it is impossible for all parts of the gearbox to be completely evenly stressed, coupled with the actual working conditions, the selection of lubricating oil and the influence of the lubrication state, which will lead to the failure of the gears. The main problems are shown in the following table. Show:

If the gear wear problem is not maintained and maintained in time, as well as maintenance, it may cause larger problems for the entire equipment. In more serious cases, it may lead to major problems and safety problems of the equipment. Therefore, real-time online monitoring of the gear box is necessary. It can help enterprises save costs and reduce the occurrence of security accidents.

-

Working principle of online oil monitoring for wind power

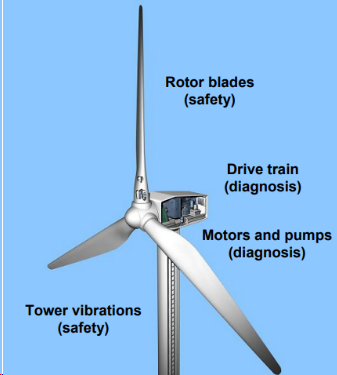

Online oil monitoring mainly monitors various physical and chemical indicators of oil (viscosity, density, temperature, moisture, dielectric constant, etc.) and particle size and distribution through basic sensors (wind power gearboxes mainly monitor ferromagnetic particles and non-ferromagnetic particles. Particles), provide real-time diagnosis solutions based on remote data analysis of the Internet of Things through wired or wireless methods, and provide data reference and suggested solutions to help customers maintain equipment in a timely manner to achieve the effect of equipment health management.

-

Contents of technical indicators of wind power online oil monitoring

Physical and chemical indicators of oil: By monitoring the physical and chemical indicators of oil such as viscosity, dielectric constant, moisture, and temperature, the aging problem of oil can be reflected, and the change of viscosity will affect whether the gear wear can be effectively lubricated, and then affect the wear problem. Moisture will affect the life of the gear, and the temperature can reflect the increased wear of the gear box. Therefore, the monitoring and analysis of the physical and chemical indicators of the oil can be used to replace the oil in a timely and effective manner, and on the other hand, the wear and tear of the equipment can be judged.

Metal wear analysis: By monitoring the concentration, quantity and size of ferromagnetic particles and non-ferromagnetic particles in the oil, the gear wear problem can be intuitively reflected, and a trend analysis can be formed in the process of real-time monitoring. If there is a big change, then it can be judged that the gear wear is aggravated, which can directly reflect the early wear and tear of the equipment.