The ASTM CFR octane Testing machine in the laboratory of refining and chemical enterprises is a key large-scale analytical instrument for inspection and analysis. In use, we often encounter problems such as reduction of calibration error and precision. According to the requirements of ASTM CFR, it is necessary to judge the troubleshooting. Diagnosis and troubleshooting often require the removal of certain parts of the engine before it can be realized. This will inevitably lead to misjudgments and excessive maintenance, increasing operating costs and maintenance costs. The “Maintenance Guidelines” of the American manufacturer Waukesha have defined and guided methods, including inspections using industrial endoscopes. In our daily maintenance and most technical services, we use Yateks M series industrial endoscope to accurately find out the faulty part without disassembling the engine. Convenient methods and tools are provided for analyzing and judging the failure and cause of the octane number machine.

1. Introduction to Industrial Endoscope

The composition of industrial endoscopes mainly includes front-end insertion tube/camera, steering control structure, display screen, host operating parts, etc. It is a kind of use of sensors, control mechanisms, etc. for industrial equipment containers, pipelines, and inconvenient disassembly equipment. It is a non-destructive testing method for observation and identification of parts below the liquid surface such as the inner surface, water, and oil, and areas that cannot be directly observed by human eyesight under special circumstances.

At present, there are more and more domestic industrial endoscope manufacturers, but not many are suitable for the inspection characteristics of octane number machines. Yateks M series industrial endoscopes are flexible in operation, the front end can be turned in any direction of 360°, and the image imaging is clear, which can meet the special needs of octane machine inspection and maintenance. The product is detailed in workmanship, compact in size, and easy to carry. It is a very cost-effective industrial video endoscope.

2. application introduction

In the frequent octane number testing work, once failures and damages occur, inspection defects will occur and cause major accidents. The traditional treatment is to ask professionals to disassemble the machine, inspect and judge with special tools, and then determine the maintenance plan. Repairs can only be carried out after foreign ordering and the presence of special accessories. This is costly, time-consuming, and progress is difficult to control. Using the M series of Yateks industrial endoscope, it is possible to determine the faulty part without disassembling the octane number machine, correctly determine the maintenance plan, and avoid excessive maintenance and failure expansion. The use of industrial endoscopes for daily maintenance can also effectively detect early failure precursors and carry out targeted maintenance to prevent and reduce the occurrence of failures and extend its operating cycle.

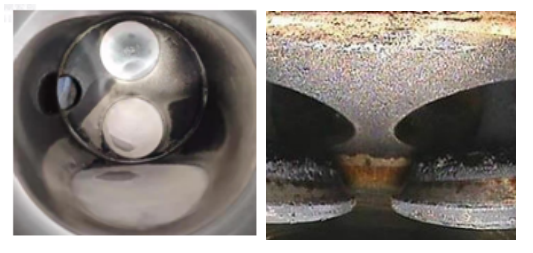

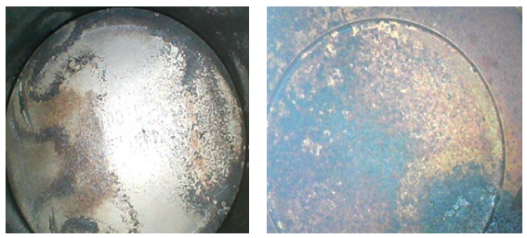

Images of the top and opening of the valve clearly show the fault

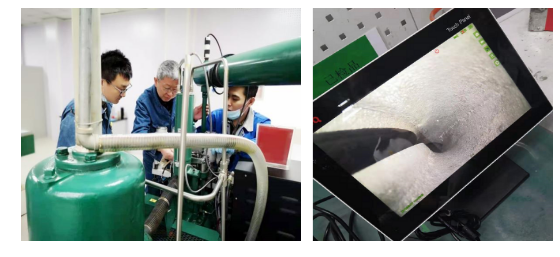

Inspection site using endoscope inspection pictures

Shenzhen Yateks Co., LTD. specializes in the development of condition monitoring products and provides strong technical support and product guarantee services. Provide customers with professional and targeted system solutions. Products mainly include oil analysis equipment and industrial endoscopes. The products have passed ISO9001, SGS RoHS, Rheinland CE safety certification, and other system certifications comply with the industry’s highest safety standards (EU standards) and form a complete quality system. Effective management and control of every aspect of the product. Using international quality parts and raw materials, through strict life tests, durability tests, vibration tests, temperature gradual change, and other tests, unqualified instruments or unqualified parts in the instrument are screened. Strict quality management control ensures high reliability and high quality of products.