What is oil analysis?

It means to understand the changes in the composition of the oil and the state of the oil itself through the detection and analysis of the lubricating oil, gear oil or other oils used in the mechanical equipment, thereby analyzing the operation of the mechanical equipment, detecting, positioning and predicting the performance of the mechanical equipment Failure to guide the repair and maintenance of mechanical equipment. The traditional method is to take oil samples from the equipment site and send them to the laboratory for testing. This process is very time-consuming and Laborious, and the equipment needs to be shut down, which may cause huge losses to the plant. Equipment shutdowns caused by lubrication failures are very common. If the state of the lubricating oil can be monitored in real time to achieve results in terms of reliability and maintenance, this will undoubtedly affect production and commercial profitability.

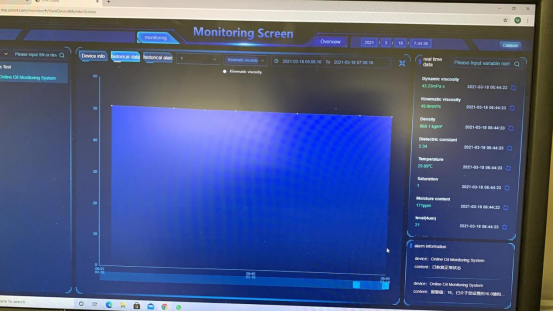

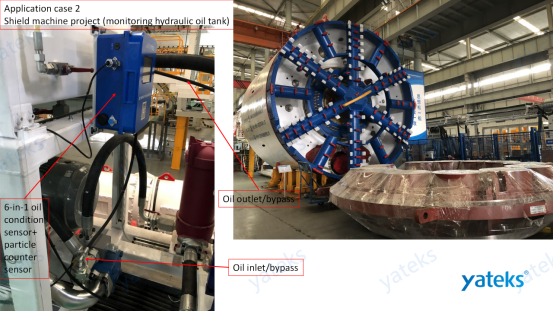

If you install an online oil monitoring sensor directly on the oil pipeline, this problem will be solved very well. The condition of the lubricant is estimated in real time through sensors, so that operators can obtain data during daily inspections, and corrective measures are taken on-site, eliminating the need for technicians to be present 24 hours a day. This will allow for the issuance of predictive recommendations to avoid catastrophic mechanical failures.

But how do you choose a suitable online oil monitoring device?

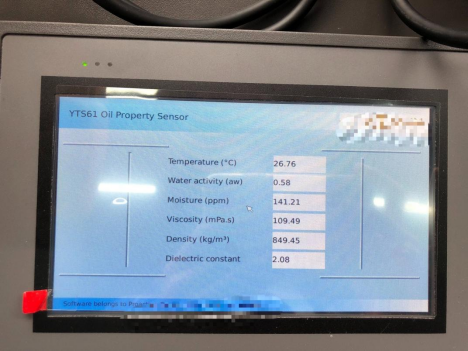

You can choose an individual sensors according to your actual situation. For example, a single sensor for testing moisture, density, temperature, viscosity, dielectric constant, particles or abrasive particles separately, or you can choose a complete online monitoring system equipment, such as Yateks’s Online Oil monitoring system which by integrating different sensors into a box, you can test different indicators at the same time with it.

According carry out online oil monitoring system, you could get the following benefits:

1.Following up and monitoring the wearing state and changing trend of equipment. Providing the scientific basis for equipment management operator make machine halt maintenance plan and extensive mainten-ance plan. Achieving the equipment condition maintenance, could detect and repair the hidden fault in time, and extend the period of extensive maintenance, to gain economic profit.

2.Because of carrying out the wearing situation monitoring, find out the equipment unusual wearing and hidden fault, guide the equipment conditional maintenance, the company could avoid major equipment accident occur and reduce the maintenance cost.

3.By carrying out oil monitoring regularly, company could find and eliminate the lubricating hidden fault of the equipment. By achieving the equipment conditional oil exchange ,and extending the period of oil exchange, the oil cost reduced, then company gain the profit.

4.By carrying out oil monitoring equipment conditional maintenance, theequipment could be advanced more reliable and was reduced accident halt, then gain the economic benefit and social benefit.