- Principles of Pollution Degree Analysis

When the lubrication or hydraulic system is working, pollutants from the outside continuously invade the system, and pollutants are continuously generated inside the system. Oil pollution is classified into potential pollution, intrusion pollution, and regeneration pollution according to the pollution source. The main types of oil pollution include: particles, moisture, air, heat, and microbial pollution. Among them, particles and water pollution have the greatest impact on the performance of the oil. Generally speaking, pollution refers to particle and water pollution. Moisture can accelerate the deterioration of lubricating oil and aggravate the abrasion of the machine. The oxygen in the water and air oxidizes the oil rapidly (the oxidation rate is several tens of times), forming a viscous compound, commonly known as sludge; after solid particles invade the system, Various wear mechanisms cause wear and tear on the components in the hydraulic system, causing system failures.

Some data show that about 70% of hydraulic system failures are caused by oil pollution. Therefore, in order to improve the working reliability of the system, it is necessary to strictly control the contaminants in the oil, especially the content of solid particle contaminants. That is, the degree of contamination of the oil. Oil pollution degree refers to the content of solid particulate pollutants per unit volume of oil. At present, NAS1638 standard and ISO4406-1987 two oil pollution degree standards uniformly formulated by the International Organization for Standardization are widely used.

- Methods of Pollution Degree Analysis

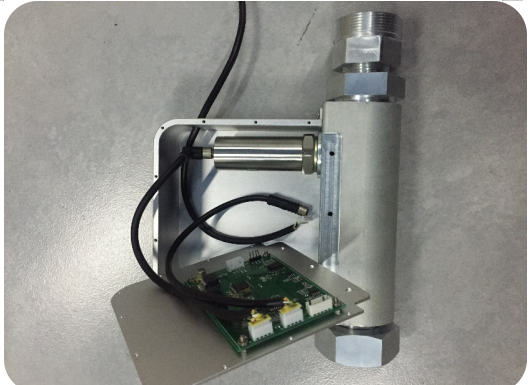

Yateks oil quality sensor is very sensitive to all kinds of oil pollution; up to 10-15 resolution, accurate detection under various harsh conditions, special grounding technology, extremely reliable and sturdy; you can grasp the oil quality of the equipment at any time; It allows you to take the initiative to maintain the equipment, avoid wasting unnecessary money and time, greatly saving oil change costs and waste oil disposal costs; reducing carbon emissions, reducing waste of oil while also contributing to the environment.

3. Pollution degree analysis function

The harm of oil pollution has aroused great attention of countries all over the world. Accurate measurement of oil contamination is the precondition of active preventive maintenance and improvement of oil pollution, and is one of the main means to improve the reliability of the system. According to the pollution degree measurement results can confirm whether the number of filters installed in the system is sufficient, whether the filter performance meets the requirements, whether the filter failure, the key components that may wear out and whether the pollutant intrusion rate changes, so as to help engineers to decide the next maintenance measures. A lot of practice shows that as long as the pollution of hydraulic and lubrication system is controlled, the quality of liquid working medium in cleanliness can be guaranteed, the occurrence of such harmful mechanical wear as abrasive wear can be prevented, and the service life of equipment can be extended.

Another example is that after a life cycle of lubricating oil, various physical and chemical indicators are often normal, but the pollution level exceeds the standard. After fine purification, the life cycle of lubricating oil can be extended, and it is possible to “service” for one or several cycles, which can save a lot of lubricating oil use funds.

Therefore applies particle counter testing instruments, such as, engine lubrication system for hydraulic system, bearing and gear reduction system of oil pollution monitoring, so as to evaluate the oil polluted situation and determine equipment wear and tear, to effectively improve the effect of oil use, prolong the service life of equipment, ensure the safety of major equipment operation, reduce failure, reduce the maintenance cost, It has profound economic and social significance.