Mabel 2020/8/4

From the global development trend of industrial endoscopes, we can understand that endoscopes are increasingly used in the automotive maintenance industry. Especially for the maintenance of vehicle power. The 4S shops of major brands of automobiles have begun to equip them with industrial endoscopes to do regular maintenance work for customers. Today, I will introduce to you a case of the Yateks M-ADV series dual-lens endoscope applied to a certain brand of engine inspection, which successfully helped customers to locate the problem of the car and prevent accidents.

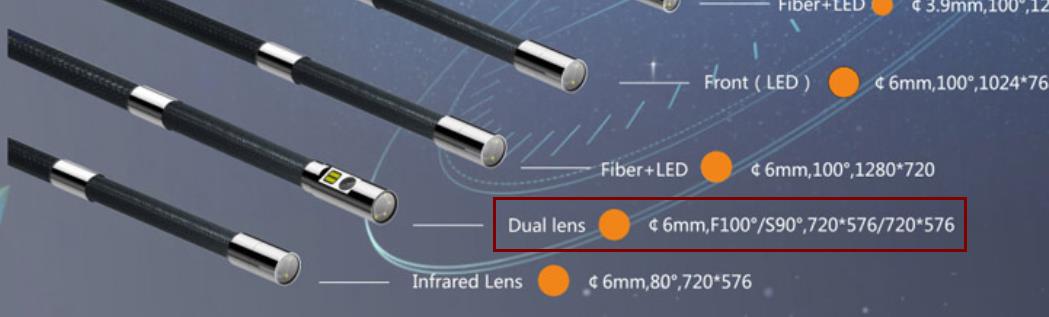

Yateks M-ADV series dual-lens endoscope, adopts the latest HD image processing technology and high resolution 640*480 screen to ensure high definition image. HDMI signal output, more convenient for external large-screen display for multiple experts to observe and analyze real-time images.

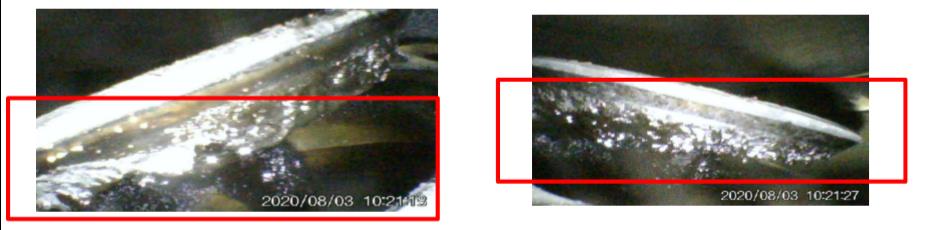

With our M-ADV series, M610DM-WLL, 6mm dual-lens, we looked at the intake valve, the top of the piston, and the top of the cylinder. It is found that the intake valve has serious carbon deposits, which is still a stubborn carbon deposit.

There are carbon deposits on the top of the piston, and the top of the piston is not obvious.

There is carbon deposit on the top of the mouthpiece cylinder, which affects the atomization effect of the mouthpiece. The type of carbon deposit is stubborn.

Conclusion: The carbon deposits in the above positions will cause the direct injection vehicle to drop in power, weaken acceleration, increase fuel consumption, difficult to cold start, engine jitter, loud noise, poor driving feeling, and even severe valve lift and cylinder pull.

Pls, contact us if you have the same application.