With the continuous development of industrial technology, the hydraulic system plays a vital role in all kinds of mechanical equipment. However, the oil quality condition of hydraulic oil directly affects the operational efficiency and safety of the equipment. In order to achieve rapid and accurate detection of hydraulic oil quality, Hydraulic oil Quick Oil Analyzer was produced, the instrument combines advanced sensing technology and analysis methods, can provide a full range of oil quality assessment results in a short period of time, to provide a strong guarantee for the normal operation of equipment.

1. Quick oil analyzer is how to achieve rapid detection of hydraulic oil?

The principle of hydraulic oil quality rapid tester to achieve rapid detection is usually based on a variety of advanced sensing technology and analysis methods. Below Yateks gives you an overview of these principles.

(1)Optical sensing technology

Optical sensing technology is often used to measure the level of contaminants and impurities in the fluid. For example, the concentration of contaminants in a fluid can be determined by measuring the change in light intensity after a fluid sample passes through a specific optical element. This method allows for rapid, non-contact detection of the quality of the fluid.

(2)Electrochemical Sensing Technology

Electrochemical sensing technology is used to measure chemical parameters such as water and acid value in the oil fluid. It is based on the principle of electrochemical reaction, by measuring the potential or current change of the electrode in the oil fluid, to infer the chemical composition and concentration in the oil fluid. This method has high sensitivity and fast response speed.

(3)Dielectric constant measurement

Dielectric constant measurement is a method to judge the quality of the oil by measuring its dielectric constant. Water and contaminants in the fluid will affect the dielectric constant, so the quality of the fluid can be assessed by measuring the change in the dielectric constant. This method is simple and quick, suitable for rapid on-site inspection.

(4)Viscosity Measurement

Viscosity is an important performance indicator of hydraulic fluid. Rapid testers usually measure the viscosity of the fluid by means of a rotating viscometer or a vibrating viscometer. These methods can accurately measure the viscosity of the fluid in a short period of time, so as to judge whether it meets the use requirements.

(5) Comprehensive analysis of the fluid

Modern Hydraulic oil Quick Oil Analyzer usually has a comprehensive analysis capabilities, can be a variety of sensing technologies for comprehensive processing and analysis of measurement results, so as to give a more comprehensive and accurate fluid quality assessment results.

(6)Automated operation

In order to achieve rapid detection, these instruments usually have automated operation. Users only need to put the fluid sample into the instrument, the instrument can automatically complete the measurement, data processing and results output and other steps. This not only improves testing efficiency, but also reduces human error.

The Hydraulic oil Quick Oil Analyzer achieves rapid and accurate assessment of hydraulic fluid quality by combining a variety of advanced sensing technologies and automated operating functions. These technologies make on-site inspection become more convenient and efficient, for enterprises to ensure the normal operation of equipment and improve production efficiency provides strong support.

2. How to use the Hydraulic oil Quick Oil Analyzer

Hydraulic oil Quick Oil Analyzer specific use, hydraulic oil oil quality detector use usually includes the following steps.

(1)Oil quality of the pre-test preparation

Ensure that the oil tester is in good working condition, in accordance with the equipment instructions for the necessary operation and calibration. Prepare the oil sample to be tested, make sure the sample is clean enough and free from impurities.

(2) Loading of oil samples

Depending on the specific instrument type and design, load the oil sample to be measured into the sample compartment or sample container of the testing instrument. Ensure that the amount of sample loaded meets the requirements of the instrument.

(3) Quick Oil Analyzer setting test parameters

Select the appropriate test parameters and methods according to the nature and composition to be tested.This may involve selecting the test temperature, pressure, spectral range, etc.

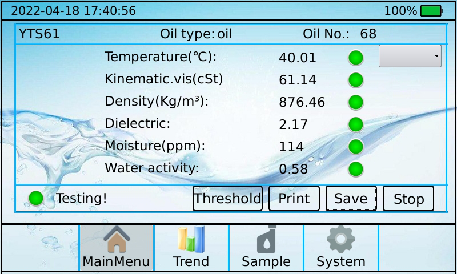

(4)Start testing hydraulic oil

Turn on the power, open the power switch, the instrument carries out power-on self-test. Enter the testing mode and start measuring the parameters of the oil sample.

(5)Read the oil detection results

Wait for the instrument to complete the measurement, read and record the parameter values of the oil sample.These values will be used to assess the quality of the oil sample.

(6)Analysing the oil test results

According to the parameter values and standard ranges provided by the instrument, judge whether the quality of the oil sample meets the requirements. If the oil sample is found to be of poor quality, appropriate measures should be taken to deal with it in time.

(7)Safety Precautions for Quick Oil Analyzer

In the use of hydraulic oil oil quality tester, should comply with the safety regulations to ensure personal safety and instrument stability during operation.Wear protective gloves, goggles and other personal protective equipment to prevent accidental injury.