Oil monitoring is usually to monitor one or more oil indicators, the main monitoring objects are particle size, moisture, abrasive particle concentration and additives, etc., and use this to determine the status.

Through optical, electrical, magnetic and other analysis methods, the collected lubricating oil or working medium is analyzed for relevant physical and chemical performance indicators, and the particles such as wear and pollutants contained in it are detected, and finally the lubrication and abrasive state of mechanical equipment are obtained. Information to judge the current working status of the equipment and predict the future working status, provide an effective basis for the correct maintenance of the equipment, and achieve the purpose of preventive maintenance. This monitoring and analysis method is oil analysis technology, also known as equipment wear Condition monitoring technology.

Oil monitoring system is divided into offline monitoring system and online monitoring system.

Off-line monitoring mainly adopts the method of regular sampling, and the collected oil samples are sent to the corresponding physical and chemical laboratories for analysis to judge the quality status and service life of the oil. In this way, the required oil sample parameters can be obtained more comprehensively, which can make a more accurate judgment on the wear state of the equipment and the condition of the oil product. But its shortcomings are also more obvious. The fixed oil sample needs to be taken out for processing offline, and the laboratory test takes a long time, which will also delay the judgment of oil quality and the implementation of measures. Instruments are also relatively expensive, and for example, wind turbines cannot be sampled for periodic testing, which is a limitation of offline testing. Relatively speaking, accuracy has become the only advantage of offline detection.

On-line lubricating oil status monitoring is to determine the operating status of the equipment through real-time monitoring of the hydraulic oil and lubricating oil in use under the condition of ensuring the normal operation of the equipment, which can effectively avoid the occurrence of major accidents and carry out targeted maintenance and maintenance. repair. Oil on-line monitoring does not necessarily measure and analyze all parameters of the oil, it indirectly reflects the relative change value by obtaining the relevant information of the monitoring index or comparing it with the standard value. Due to the influence of online physical conditions, the accuracy has an error range of about one level from the offline detection value. Enterprises generally choose the appropriate detection method according to their own needs and conditions.

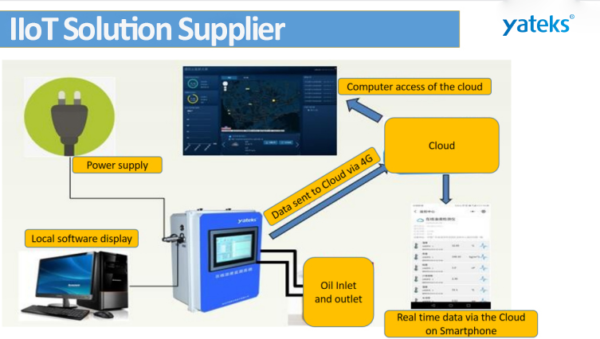

Yateks focuses on condition monitoring and equipment fault diagnosis technology, with a complete product chain. Including oil online monitoring system and laboratory analysis equipment. If you have such convenient needs, we can provide you with customized solutions.