Oil is considered “blood” in the eyes of equipment people, which is more important! With regular offline testing already well established, is on-line monitoring of oil quality still necessary? This requires an analysis of the advantages and disadvantages of the “offline testing” method. If “offline testing” can meet the needs of oil. then “online testing” is not necessarily important.

First, the advantages of offline testing

1, off-line testing environment for the static ideal state. the data is relatively stable.

2, to facilitate multi-parameter testing.

3, really did not think out

Second, the defects of off-line testing

1, the cycle is long, generally 6-12 months once. Detection and reporting take some time. Does not guarantee timeliness.

2, there are limitations in taking oil samples. sampling points rely on experience, the concept of average.

3, the possibility of secondary contamination of sampling, affecting the authenticity.

4, air pressure, temperature, humidity, and other testing environment is different, resulting in the results of the difference will be very large. such as the oil in the micro-water content and other parameters.

5、The data is single and contingent, and cannot be used as the basis for equipment evaluation.

In summary, the off-line detection of oil products still has many defects and cannot meet the needs of the whole life cycle management of oil products.

Advantages of online monitoring.

1.real-time data.

2.dynamic data with representativeness.

3.Traceability of data.

4.elimination of sampling and avoidance of secondary pollution.

5.online monitoring content not only includes quality indicators. such as contamination, moisture, viscosity, etc. but also can integrate pressure, flow, temperature, liquid level, and other operating indicators, more comprehensive response to the lubrication status.

6. the accumulation of big data analysis of equipment health, is the trend of equipment management

7. save labor costs

The advantages are already very obvious. There is another way of saying: we all know that online monitoring is good, but the cost is too high, we can’t afford to go on.

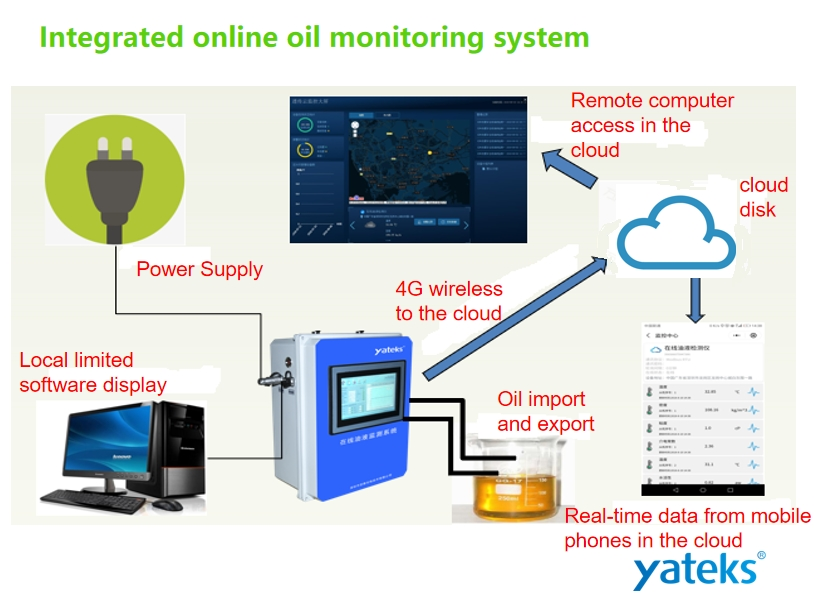

In response to the needs of the market. Yateks has launched an online oil detection system that can meet the needs of all aspects. There are sensors launched for testing standards. like testing oil quality, moisture, viscosity, etc. Online oil monitoring system. online oil analysis unit includes a five-in-one sensor (viscosity, density, contamination, temperature, and moisture measurement), a six-in-one sensor (viscosity, density, contamination, temperature, moisture, and abrasive particle measurement), the sensor is highly integrated, the device is easy to fix, the collection box can realize the sensor data acquisition and signal transmission, and can display the monitoring data in real-time.

Conclusion.

Online oil monitoring is needed and necessary and is an inevitable trend of modernization, digitalization, and intelligent equipment management. The correct attitude should not be to reject, but to accept, popularize and improve.