Ⅰ. Introduction

YJS150 oil particle particle is made in the principle of light extinction (or light-blockage) and used to detect the size and quantity of solid particles in liquids. Particle counting to detect the degree of contamination of liquids, the fastest and most objective analysis, using laser-optical particle counters which automatically counting the pollution particles using a flow measuring cell and classify them according to their size.

Ⅱ. Measuring Principle

YJS150 Portable Particle Counter applies the principle of light extinction (or light-blockage) stipulated by ISO4402/ISO11171 to detect the oil contamination and is featured with rapid detection, strong anti-interference, high precision and good repeatability.

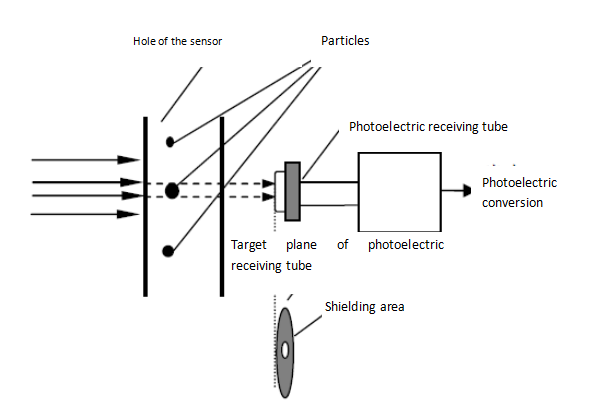

As showing in below picture, The parallel beams cross the flow chamber of the sample with section A vertically upon the photoelectric receptor. When there is no particle in the liquid, the output voltage of the circuit will be E. When there is a particle with a projected area of a in the liquid which blocks the parallel beams with the transmission light weakened, the circuit will output a negative pulse of E。{E。=(a/A)×E }.If the particle is spherical or described as its diameter equal to d with 10v of E。=7.854×d2/A.

Which means there is a linear relationship between the projected area and the pulse voltage amplitude.

Ⅲ. Application

Ⅲ. Application

Let´s start with THE IMPORTANCE OF PARTICLE COUNTING:

Why measure particulate contamination in liquids so important?

Liquid purity plays an important role in a variety of industries for a diversity of reasons, the particles in the micrometer range that are not visible to the human eye are particularly critical. with a convenient ,effective and accurate way to monitor the pollution status, to early predict the possible damage or fault, avoid great lose and protect asset.

hydraulic systems

- Industrial gears

- Turbines

- Transformers

- Component purity(automotive industry and medical technology)

- Water treatment

- Quality control of pharmaceuticals

The first three examples are mainly concerned with the early detection of abrasion damage or beginning oil wear and filter monitoring. For transformers oil, it can tell you the oils aging condition degree with contaminates. In the other areas, the purity of the liquid or the product and compliance with specified limit values is of central importance.

Knowing the contamination can help to monitor safety risks, environmental and health hazards as well as improve quality defects.