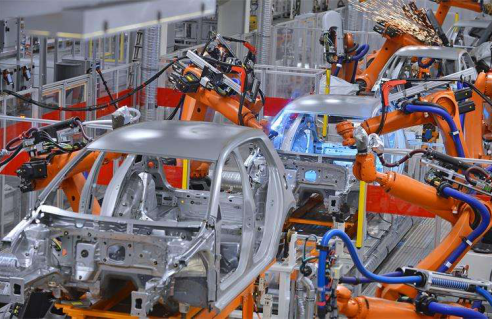

As intelligence and digitization continue to be integrated into automobiles, automobile manufacturing is transforming and upgrading to a higher intelligent “new manufacturing” stage. As non-destructive testing equipment, electronic video endoscopes are used in the quality control and defect detection of automotive powertrains. In terms of production and maintenance, the industry’s leading automakers and auto sales companies rely on Yateks Industrial Endoscopes.

A vehicle powertrain refers to a series of components and components that generate power on a car and transmit it to the road. In a broad sense, it includes engines, gearboxes, driveshafts, differentials, clutches, and so on. But under normal circumstances, people prefer to use chivalrous terms, thinking that the powertrain only refers to the engine, the transmission, and other parts integrated into the transmission, such as the clutch/front differential.

The application of Yateks industrial endoscope in automotive powertrain inspection involves the following aspects:

- In the manufacturing stage, the quality control and assembly inspection of auto parts can be carried out, and the assembly quality can be checked; after assembly or a certain process is completed, check whether the assembly position of each component meets the requirements of the drawing or technical conditions; whether there is assembly defect. In this way, the quality of the car is guaranteed from the source.

- It can be used for internal defect inspection and fault location of power equipment, gearbox, etc. during the putting into use phase. It is mainly used for detecting and diagnosing the wear, coking, and blockage of automobile engines, cylinders, hydraulic components, fuel pipes, engines, mufflers, conveying and air conditioning systems, differentials, water tanks, fuel tanks, gearboxes, etc., improving work efficiency, reduce repair costs, and avoid damage caused by multiple disassembly and assembly of mechanical parts. In the cleaning and maintenance of automobile engines, endoscopes are also indispensable daily tools. At the same time, it is easy to operate, flexible, compact, and easy to carry. The soft, small and bendable insertion tube can reach any hidden part that needs to be checked.

Of course, whether it is a traditional engine car or a new energy-powered car, the purpose of the above-mentioned detection is to find hidden problems as early as possible to ensure product quality or driving safety. For new energy vehicles, an endoscope can also be used to detect the condition of the battery and its related devices. In addition to detecting defects, Yateks industrial endoscopes can also eliminate redundant objects in auto parts: use a video probe equipped with a manipulator to grab the extra objects remaining in the auto parts, thereby eliminating potential safety hazards.