1.What are the possible failures of marine oil extractors?

Marine diesel engine is a complex thermal machinery. As the core equipment of the ship, diesel engine plays a vital role in ship safety. However, the structure of the diesel engine is complex, more parts, the body is in a high temperature, high pressure environment, so the possibility of failure is relatively large.

Some failures will lead to ship diesel engine performance degradation, such as black smoke, increased fuel consumption, etc. This gradual failure is often gradual occurrence, can be predicted through early diagnosis, such as cylinder wear monitoring, lubrication system quality monitoring.

Some faults will cause diesel engine performance failure, such as diesel engine burning tile, holding cylinder, etc., also often due to gradual failure is not found and resolved in a timely manner, before the occurrence of sudden failure. In order to protect the normal work of marine diesel engine, further extend the service life of marine diesel engine, early detection and elimination of these faults is very important.

2.Online monitoring system technology program

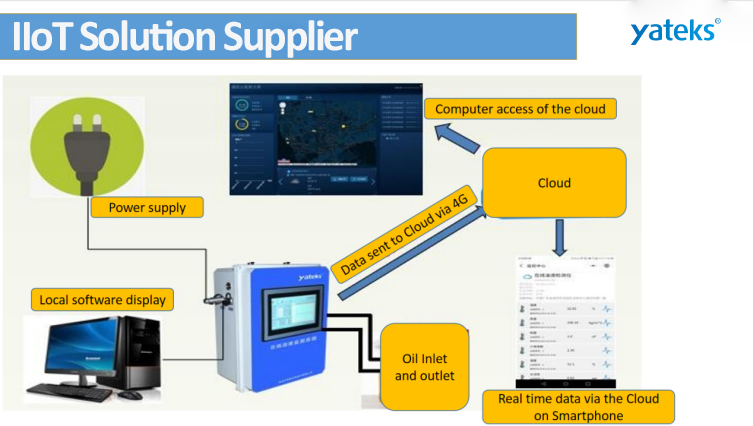

Technical Solution: It is proposed to increase the online oil monitoring system for the diesel engine lubrication system, real-time monitoring of a number of index parameters of the lubrication system, combined with the lubrication system of the normal range of standards, monitoring the lubrication of the trend of various data fluctuation range, to determine the quality of the system lubrication, lubrication equipment wear and tear, and real-time diagnosis of the engine to prevent the gradual failure.

3.Common on-line monitoring system for marine oil fluid

The on-line monitoring systems for oil liquids on ships can vary according to the specific application requirements and monitoring purposes. The following are some common online monitoring systems for marine fluids:

Engine oil online monitoring system: used to monitor and evaluate the quality and performance of engine oil, including the monitoring of viscosity, contaminants, moisture and other parameters.

(1)Lubricating oil system online monitoring system:

used to monitor the quality of the oil in each lubricating system of the ship, including the monitoring of the degree of contamination of the lubricating oil, acid value, moisture and other parameters.

(2)Diesel oil online monitoring system:

used to monitor the quality of diesel fuel on board ships, including the monitoring of fuel oil pollutants, sulfur content, moisture and other parameters.

(3)On-line monitoring system for oil-water separator:

it is used to monitor the quality of oil in the ship’s oil-water separator, including the monitoring of separation effect, oil-water content and other parameters.

(4)Hydraulic oil online monitoring system:

it is used to monitor the quality of oil in the ship’s hydraulic system, including the monitoring of viscosity, pollutants, water and other parameters.

Case: After years of experience in equipment troubleshooting, the equipment management of a research institute believes that the online monitoring parameters of our company are suitable for monitoring the engine lubrication system of its unit, as well as repeatedly communicating with our company about the online oil monitoring program, and finally determines to support the technical program of our company to monitor, analyze, and warn for several years.

Oil type: No. 320 gear oil

Monitoring indicators: power viscosity, density, temperature and metal abrasive particles