The Tunnel boring machine is a large-scale engineering machine used in large infrastructure projects. Such as highway tunnels, railway tunnels, and subsea tunnels. The environment in the tunnelling work is very harsh. It is faced with large dust and various wet geological layers, such as soft soil bottoms, rock formations, etc. The environment is very unfavourable for the equipment. After years of research and development, Yates has accumulated rich experience in oil monitoring. An intelligent online oil monitoring system. It can check the lubricating oil wear status of the shield machine in real-time. It can help customers understand the health of the equipment oil in real-time. And protect the equipment from damage.

1. Working principle of Working principle of tunnel excavator

The basic working principle of the Tunnel boring machine is that a cylindrical steel component moves forward along the tunnel axis while excavating the soil. The shell of the cylindrical component is the shield. It acts as temporary support for the excavated section of the tunnel that has no line. Withstand the pressure of the surrounding layers. And sometimes withstand the pressure of the groundwater and keep the groundwater out—excavation, dumping, lining and other operations under a shield cover.

2. Customer Difficulties

The shield machine relies on two major systems for support in the tunnelling work. One is the hydraulic system. which is responsible for the activities of the equipment when it travels. One is the gearbox cutter head system. which is responsible for the operation of the cutter head excavation and withstands excellent strength. The hydraulic system and gearbox system have accumulated long-term high-load work, which will cause the hydraulic system oil to deteriorate. And produce a large number of pollution particles and gearbox gear fatigue wear. Once the equipment fails, it will cause damage to the equipment. Delays in the progress of the project are unacceptable.

3.solution

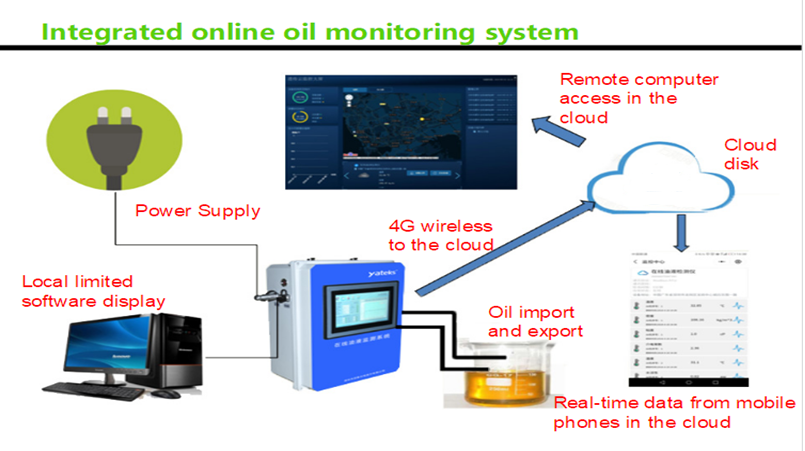

Online oil monitoring system A set of oil online remote intelligent detection and diagnosis systems. It is based on the IoT platform. Modular design is realized internally.

4. scope of test:

Real-time monitoring of critical indicators. Such as trace moisture, water content, viscosity, dielectric constant, density, temperature, water activity, pollution degree, and abrasive metal particles of the oil. Realize the intelligent remote monitoring—diagnosis of the oil condition of the equipment. And the operating status of the equipment. This product integrates advanced oil sensors, IoT cloud platform and big data technology, combined with yateks’ years of accumulated core data algorithms for oil monitoring.

- Significantly improve the accuracy, timeliness, and effectiveness of data analysis.

- Help customers realize intelligent remote monitoring of equipment. Predictive maintenance improves equipment operation efficiency.

- Reduce the total cost of equipment maintenance and lubricants. Provide comprehensive real-time online monitoring of oil without dead ends.

- System module composition

The monitoring system comprises several system modules, such as sensor module, oil control module, chassis structure fixed module, data processing module, and a data sending module. Realize real-time oil monitoring and data processing.

6.System installation method

System installation location: hydraulic oil tank filter unit

Oil collection position: before the fuel tank filter

Oil return position: oil tank

Hydraulic system monitoring indicators:

kinematic viscosity, dynamic viscosity, density, temperature, dielectric constant, trace moisture, moisture content, cleanliness.

The online oil monitoring system of yateks is installed on the hydraulic circulation system of Tunnel boring machine. it can monitor intelligently 24 hours a day. It realizes the digitization and intelligent operation and management of equipment. Reduce the cost of equipment maintenance for enterprises and increase equipment production efficiency.