Reporter: Nancy Dong

Date: 2019/8/14

The oil monitoring technology obtains the lubrication and wear information of the machine by analyzing the performance changes of the lubricant (or working medium) in the monitored equipment and the wear particles carried, evaluate the lubrication and operation status of the equipment to find potential faults. Judge the degree of failure, the type, the location, and the cause of the failure, to guide the maintenance personnel to scientific management, condition-based maintenance, and improve equipment reliability.

What is the specific significance of oil monitoring?

First, the quality of the lubricant:

Through the analysis and testing of the physical and chemical indicators of various lubricating oils, the quality of lubricating oils is evaluated against the national quality standards, and guide enterprises to select good quality and suitable lubricating oils, including:

(1) New oil quality assessment

(2) Evaluate whether the oil is suitable selected

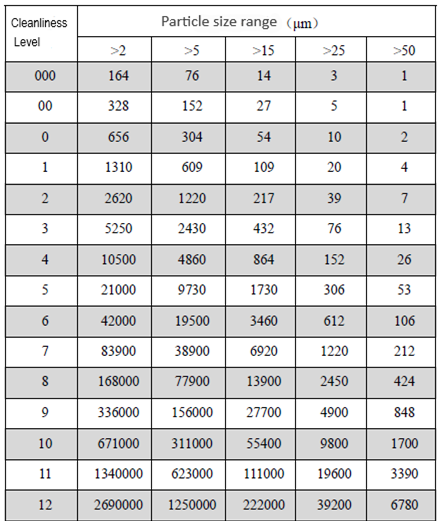

(3) Determine the level of cleanliness

Second, equipment lubrication status evaluation:

Through the regular tracking and monitoring of the main physical and chemical indicators of the lubricating oil in the equipment, find the problem in time of the degree of deterioration of the oil and the cause of the pollutione, and evaluate the lubrication state and help the the enterprise to adopt a reasonable lubrication method and oil change period.

- Simulating the use environment and bearing condition of lubricating oil, testing the performance of lubricating oil (overall)

- Study on oil product degeneration (overall)

- Study the sealing performance of lubricating systems and the performance of lubricating oil additives (subdivision)

- Evaluate the degree of factory cleaning cleanliness of the lubrication system and establish relevant standards (new lubrication system)

- Find the deterioration, decay degree and cause of deterioration of the oil used in the lubrication system, and determine the oxidation value and the additive content (monitored by the lubrication system)

- Evaluation of the wear resistance of hydraulic lubrication systems (test lubrication system)

- Guide the company to adopt reasonable lubrication methods and oil change intervals (management lubrication system) through regular tracking and monitoring of oil.

Third, equipment wear fault diagnosis

Through the quantity and qualitative analysis of the wear of metal particles in the oil, to monitoring and diagnosing the wear and failure status and causes of the main friction pairs of the diagnostic equipment, and guide the enterprise to take timely maintenance measures to ensure the safe operation of the equipment. include:

(1) Lubrication system fault location, fixed point maintenance equipment

(2) Judging the degree of wear during the operation of the analytical equipment, analyzing the change in the total amount of wear, obtaining the zero point of wear, and evaluating the lubrication state of the equipment

(3) Through the failure of the lubrication system to evaluate the material and structural rationality.

Equipments are the foundation of enterprise survival and development. Through professional oil monitoring and analysis, it can improve the equipment management level and avoid the occurrence of major accidents, extend the service life of equipment effectively.

According to previous studies: The application of oil monitoring and analysis prevents huge losses and save 2 million tons of heavy oil and 10 billion KWH of electricity from improvement of mechanical lubrication, adopt energy-saving lubrication technology and energy-saving lubricants. The total value is equivalent to 6 billion to 10 billion RMB in China.

At the same time, save about 30~50 Billion cost due to good lubrication and monitoring for mechanical equipment, reducing the shutdown of equipment to replace spare parts.

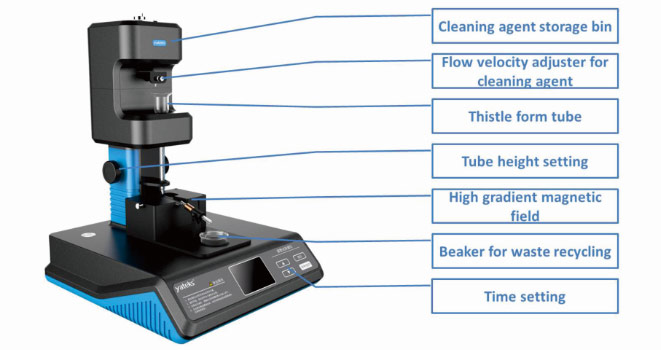

Yateks, a world-class supplier of NDT and oil monitoring equipments, committed to being a world-class brand of advanced monitoring and technology instruments.

Yateks is committed to providing professional oil monitoring instruments for global customers. We have established a high-level R&D team lead by Doctor and hired two academicians as senior technical adviser.

So far, Yateks has gained 22 invention patents, ISO9001, CE, ROHS,WEEE and many other certifications. We adhere to independent innovation, high-quality products to win the market. Our analytical ferrography, ferrous debris monitor, oil particle counter sensor has made good response both at home and abroad.

And Yateks has built the strong relationship with Petro China, Sinopec, Sany, BMW and other world tops 500 enterprises.