The internal combustion engine unit is the main power source for large ships, construction machinery, offshore operation platforms, and nuclear power plants. Once a failure occurs, much mechanical equipment will lose its power source. Their lubrication systems are subject to harsh conditions. especially for platform vessels operating at sea. The reliability status monitoring of the internal combustion engine is more important.

The online monitoring of the oil of the internal combustion engine is very convenient. Just set up the oil sump under the oil return line in the oil pan and install the lightweight online monitor. The obtained data can then send to the central control room of the engine room via wired transmission. This enables maintenance engineers to discover potential lubrication failures of each mainframe in time on the console.

1.The main technical indicators of “online monitoring system for internal combustion engine oil”:

(1) Oil viscosity:

adopt fluid vibration sensing technology. It can detect the viscosity change of internal combustion engine oil. When the internal combustion engine has fuel dilution or coolant pollution due to mechanical failure or damage, it can detect and alarm in time.

(2) Contaminated water:

using liquid dielectric constant sensing technology. It detects changes in moisture content in engine oil. When the engine is polluted by the coolant due to mechanical failure or damage, the alarm can detect in time.

(3) Wear particles:

use the wear particle detection technology. Detect the wear of lubricated moving parts such as cylinder blocks, pistons, and bearings of internal combustion engines.

(4) System configuration:

According to customer needs, the above sensing technologies can use alone or in combination with multiple sensing technologies. To obtain comprehensive oil quality and contamination status information of the hydraulic system.

2. Items to confirm before installation :

(1) Select the oil port:

Try to choose a point where there is oil immersion (at the horizontal straight section) of the hydraulic system return pipe bypass (branch) of the equipment. where the oil pressure is low and the flow is small.

(2)The pressure parameter of the oil port is determined:

zero-pressure oil needs to be equipped with a gear pump for pumping. pressures above 1.5MPA need to be equipped with a pressure-reducing valve. 0.3MPA~1.5MPA normal pressure does not need to add a pump and does not need to add a pressure reducing valve.

(3) Oil return port selection:

try to return the oil return port to the fuel tank, because the fuel tank has zero oil pressure.

(4)Try to add ball valves and flow control valves to the oil inlet (take oil port). and add ball valves to the oil outlet (return port) as much as possible. (The ball valve is convenient for maintenance, and the flow control valve can adjust the flow and flow rate).

(5)Confirm other parameters:

oil temperature, flow rate, pipe diameter, medium, and thread interface specifications.

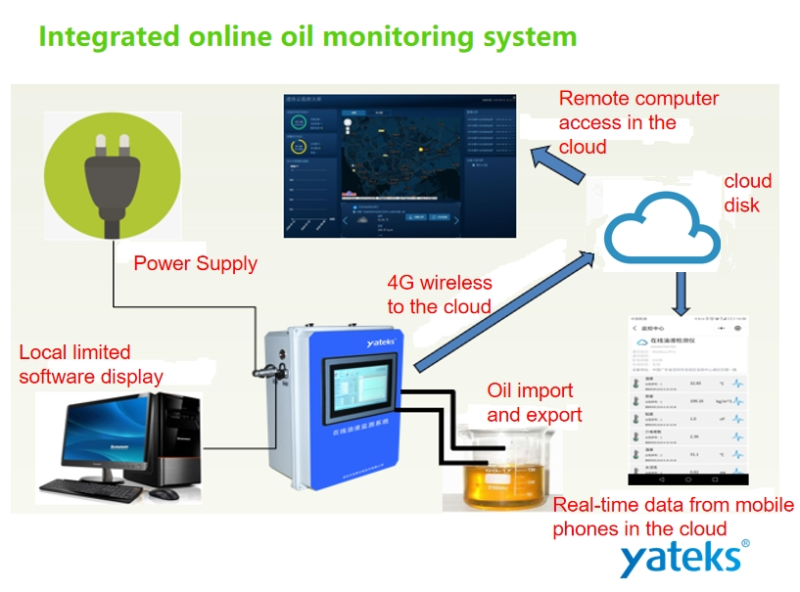

Yateks is a cloud data-based condition monitoring platform that helps users monitor their equipment in real-time. The Yateks Industrial IoT system helps users receive real-time monitoring results from sensors installed in the oil circuit. Connect to the cloud platform in real-time, convert it into key information about equipment and oil in use, and guide users in equipment maintenance work