Date: 2019/06/11

Industrial equipment need equipment management and maintenance with lubricating oil regularly. When the lubricating oil is insufficient to meet the lubrication requirements of mechanical equipment, it is necessary to replace the lubricating oil in time to ensure the periodicity and reliability of lubricating oil detection and equipment diagnosis. Correct access to representative oil samples is a crucial part. In this paper, we explains how to extract lubricants from mechanical equipment from various dimensions such as lubricant sampling cycle, sampling location, sampling volume and sampling operation procedures.

The following are the main methods of lubricant sampling.

- Sampling should be carried out by a specialist. Sampling personnel should be professional responsible.

- The sampling should preferably be a colorless and transparent glass bottle, but considering that the glass bottle is easily broken and leaked, a dry plastic bottle is good substitute. After sampling, you should immediately label and carefully fill in the relevant content on the label.

- The sampling cycle: sampling equipment oil at regular intervals.

- Sampling amount: 150-300ml for each sampling, 500ml for viscosity and water sampling, and the general sampling amount is three-quarters of the sampling bottle.

- Sampling environment: Samples should be carried out under the operating conditions of mechanical equipment. In special cases, samples should be taken within 30 minutes after stopping the mechanical equipment.

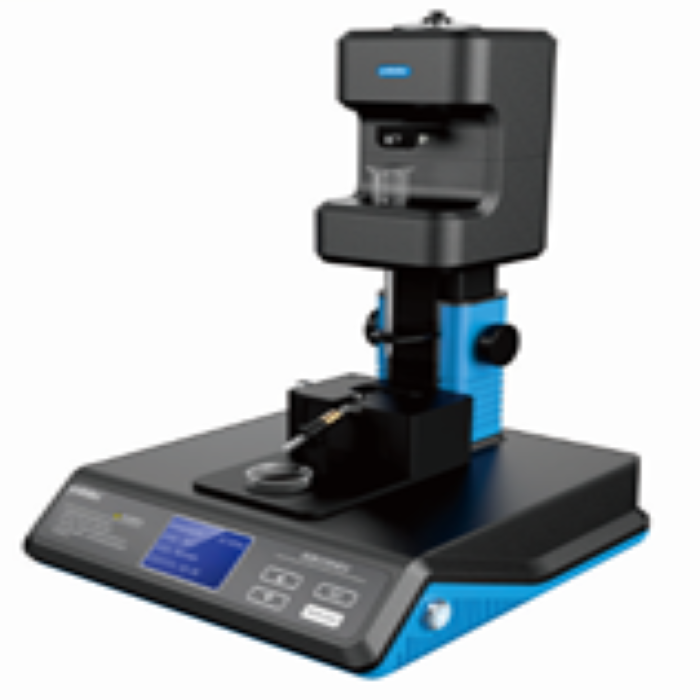

- Sampling part: For medium and high speed diesel engines, one system oil sample can be taken at a time; for a single cylinder independent lubrication system, the diesel engine should be sampled in separate cylinders. The sampling part is generally set in the return pipe drain valve, filter front, crankcase. When sampling the lubricating oil, during the operation of the sampling valve, it should be noted that the oil should be completely flushed over the sampling valve before the sample oil is taken. The purpose of this is to remove the impurities and the upper part of the sampling valve. The residual oil of the sub-operation ensures the accuracy of the sampling. Except the sampling parts mentioned above, it’s more special when the sampling position of the lubricating oil is Analysis of fuel tanks, engines. The method of operation : Screw the sampling bottle to the sampling pump, and then pour the sampling tube on the sampling pump into the tank. After the sampling pump is started, the oil in the oil tank will flow to the sampling bottle under vacuum. Once the sampling site is determined, each sampling should be performed at the same location.

- When sampling, it is necessary to ensure that the sampling port is clean and free of impurities. The oil should be taken out from the sampling port and then the oil sample should be sent for inspection to ensure the uniformity and representativeness of the oil sample.

- Immediately close the sample cap after sampling to prevent leakage (no need to wipe the sample bottle with any items!) Then wipe the sample bottle clean and stick the label (sampling card) to prevent it from falling off. Keep the label clean, and try to avoid oil contamination.

- When the oil monitoring and sampling inspection of a certain equipment is carried out for the first time, a new oil with the same oil brand number as the equipment shall be provided for comparison. When the equipment is replaced with different grades of oil, Re-send the brand new oil to ensure continuity and accuracy of the monitoring results.

- After the equipment takes the oil sample, it will be sent to the monitoring center for testing.