In recent years, with the extension of the operation or maintenance cycle of petrochemical equipment, the expansion of production scale and the continuous development of new processes, the complex process environment has increasingly higher requirements for testing products. Endoscope inspection is a kind of inspection technology that has gradually been widely used in recent years with the development of industrial endoscope manufacturing technology. Through industrial endoscope inspection, the staff can check the defect size of pressure vessel and pipeline welds. Defect characteristics are accurately judged. Through regular inspection, the staff can find out whether there are new defects in the use process in time, so that the staff can be reminded to repair the equipment in time to achieve the goal of equipment and personnel safety.

Applications of industrial endoscope in petrochemical industry

Industrial endoscopes can be used for the detection and inspection of internal defects such as storage tanks, heat exchangers, spherical tank trucks in petroleum refineries, pipeline facilities in the chemical industry, special inspection institutes and pressure vessel production units. At the same time, there is no need to disassemble the inspected equipment during the inspection process, so it is a very cost-effective inspection solution.

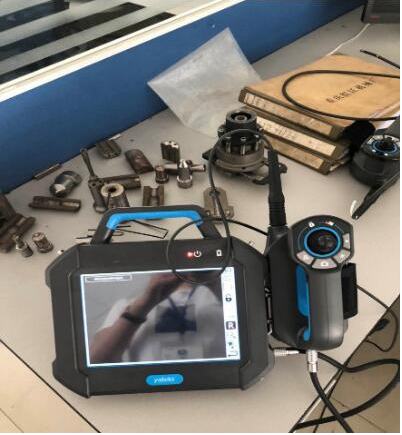

Video endoscopy inspection technology in the industrial condenser tube, compressor, heat exchanger tube internal inspection, weld inspection, tube wall deposition, pharmaceutical, food stainless steel pipeline corrosion and cracks, overheating inspection and whether there are leaks Inspections, electroplated pipes, and circular weld inspections are widely used. The image processing system and recorder of the video endoscope can effectively record, store and process the inspection defects at any time to ensure the archiving of the image data.

Application in different devices

Industrial endoscopes for heat exchanger

The heat exchanger is the equipment for heat exchange. It is the necessary equipment to reach the process temperature in the chemical industry, and it is also the most widely used and most important equipment in the chemical industry. The endoscope mainly detects the corrosion of the heat exchange tube of the heat exchanger, and the heat exchange tube with anti-corrosion coating also needs to use the endoscope to check the integrity of the coating during the manufacturing and use process. At present, many domestic chemical companies have many scrapped heat exchangers, some as many as dozens, which are scrapped due to the corrosion of heat exchange tubes. The endoscope can help customers find problems early, thereby helping customers solve unplanned shutdowns.

Industrial endoscopes for heating furnace tube

The pressure reducing device, catalytic reforming device, hydrocracking device, etc. commonly used in the petrochemical industry have heating furnaces. Heating furnaces are widely used in the petrochemical industry and are the top priority of all devices. Coking of the heating furnace tube greatly increases the temperature of the heating furnace tube, thereby increasing the oxidation and corrosion of the furnace tube, which may cause the furnace tube to rupture seriously. Therefore, the endoscope is used to detect the coking condition of the heating furnace tube in the overhaul.

Industrial endoscopes for main pressure pipelines

some pressure main pipelines connected with equipment in the petrochemical industry. This part of the pipeline belongs to the category of high temperature and high pressure. Once the internal corrosion and foreign matter blockage, it is easy to cause serious consequences such as pipeline explosion. Therefore, regular video inspection of the main pressure pipeline and treatment of internal problems are vital to the safety of the entire system.

Coking plant heating furnace tube: In the petrochemical industry, there is a coking plant. The medium in the heating furnace tube of this workshop is generally residual oil. The concentration and viscosity of the medium are relatively high, and it is easier to coke in the furnace tube. After mechanical defocusing, an endoscope is needed to detect whether there is any coking on the tube wall. The heating furnace tube in the coking plant is more prone to coking than the heating furnace tube in other devices, so more inspection is needed.