In order to solve various faults during the operation of wind turbines, effectively reduce the losses caused by faults, and avoid major faults, the on-line oil monitoring system S6FJ of Yateks has played an important role. The system uses oil monitoring technology to track, monitor and analyze the conditions of lubricating oil, wear metal particles in the oil, and contaminant particles in wind power equipment, obtain information on the lubrication and wear status of the equipment, and monitor the quality of the oil. The change trend of the equipment is used to evaluate the working condition of the equipment and predict the failure to determine the cause of the failure. The test results prove that the system can reasonably arrange the maintenance time according to the equipment status, reduce the impact of downtime and regular maintenance on production, and improve the productivity. It is an effective means to guide the fan lubrication management and operation and maintenance.

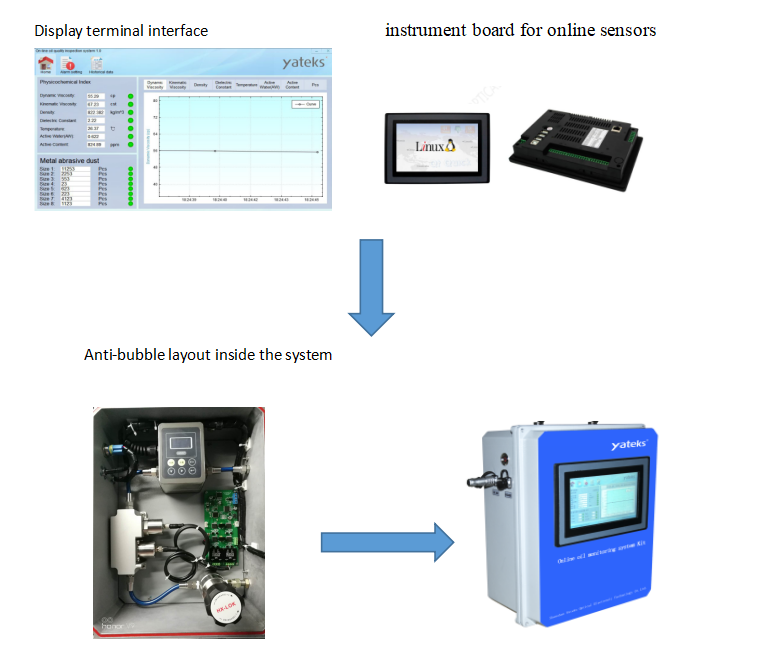

Advantages of Yateks online oil monitoring system S6FJ

- Real-time monitoring. It usually only takes a few minutes to tens of minutes to complete an online monitoring. The results are automatically entered into the database.

- No need to sample. Analyze the oil in the oil return pipe or gear box directly, avoiding the problems of unrepresentative sampling and secondary pollution. It also solves the problems of difficult sampling systems and the labor cost of sampling. For most monitored systems, offline laboratory analysis can fully meet the needs without the above-mentioned problems. However, for some key equipment, such as equipment on continuous production lines, equipment that cannot be easily shut down, and large equipment that cannot carry out regular oil monitoring, online monitoring is a better choice. First of all, because the primary purpose of oil condition monitoring is the early detection and early warning of oil deterioration, pollution and mechanical wear. The laboratory’s oil testing can only provide the current state of the oil, and cannot provide the changing trend of the oil quality. It can only be used as a criterion for finding the cause of the failure after the equipment failure occurs. Secondly, early detection of mechanical wear is the basis for equipment condition-based maintenance. Online monitoring can provide equipment wear trend graphs based on changes in oil status, and can arrange maintenance before equipment serious wear or failure occurs to reduce equipment damage; again, according to equipment Reasonably arrange the maintenance time to reduce the impact of downtime and regular maintenance on production; thirdly, the mean time to failure of the equipment is increased, and the productivity is improved. Therefore, the line-type oil monitoring device is a useful supplement to the offline analysis of the laboratory. It can detect and warn the oil deterioration, pollution and mechanical wear in the early stage, and cut off the inducement of abnormal equipment wear from the root cause.

If you want to know more product information, please send an email to info@yateks.com