Viscosity is an important physical and chemical performance index of lubricating oil. Whether the viscosity of the lubricating oil is reasonable directly affects the lubricating effect of the equipment.

If the viscosity is too large, the running resistance will increase, the power consumption will increase, and the lubricating oil will not flow to the parts that should be lubricated quickly and in time, which will affect the normal lubrication and increase the mechanical wear.

If the viscosity of the lubricating oil is too small, it is difficult to form an oil film of sufficient thickness, so that a normal and continuous lubricating layer cannot be guaranteed between the friction surfaces, and it will also cause abnormal mechanical wear.

Therefore, in the oil monitoring process, the oil viscosity must be detected. This is an important basis for judging the lubrication status of the equipment and determining whether to change the oil. The viscosity index is very important for the lubrication system of the equipment.

Yateks provides customers with solutions for fast and accurate viscosity measurement

Combined with many years of monitoring and diagnosis experience, Yateks has developed a multi-functional comprehensive oil analyzer. The built-in temperature control module can accurately control the temperature of 40°C and 100°C, and the temperature control accuracy is 0.1°C, which solves the problem of on-site viscosity measurement. It only takes a few minutes to quickly and accurately measure the viscosity and density of lubricating oil, temperature, dielectric constant and water content. If equipped with an abrasive particle sensor, the wear of the equipment can also be measured. The instrument has the advantages of convenient operation, flexible control, real-time detection results and online analysis of historical data, data export, good stability and reliability.

Features of YOT series of multi-function comprehensive oil analyzers:

1. 7-inch large screen, easy to operate, all operations can be completed by using the touch screen;

-

The test results are displayed and saved in real time;

-

Historical data can be analyzed online, and data can be exported;

-

It has a unique anti-corrosion and anti-pollution coating, and has an oil guide groove and an oil box, which is convenient to export oil leakage from the instrument;

-

Well-designed exhaust vents can effectively prevent dust, stains, etc. from entering the inside of the instrument;

-

Excellent long-term stability and reliability;

-

The viscosity sensor is uniformly equipped with a high-precision temperature control system (temperature control accuracy 0.1°C), and the constant temperature is 40°C.

-

Particle or abrasive sensor, choose one.

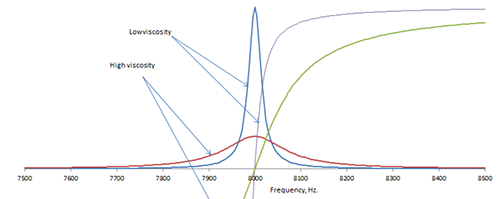

The measurement principle of the viscosity of this instrument: the circuit sends a continuous sinusoidal excitation signal to the piezoelectric crystal, which drives the blade to vibrate continuously in the liquid. The density value is obtained by measuring the resonance frequency; the viscosity value is obtained by the excitation current required to maintain a fixed amplitude; the viscosity and density measurements are obtained by real-time detection of the vibration frequency and quality factor, combined with the optimal algorithm.

This instrument is the result of Yateks’ full market data research to solve the actual needs of customers. The good stability, accuracy, and ease of use of the instrument make the product popular with customers as soon as it is launched.