Bearings are a very important component in contemporary mechanical equipment. It mainly supports the mechanical rotating body and reduces the friction coefficient during its movement. In this way, the rotation accuracy can be guaranteed. Moreover, the degree of bearing wear is related to whether the machine can work normally, so it is necessary to carry out regular maintenance on the bearing to ensure the normal operation of the machine.

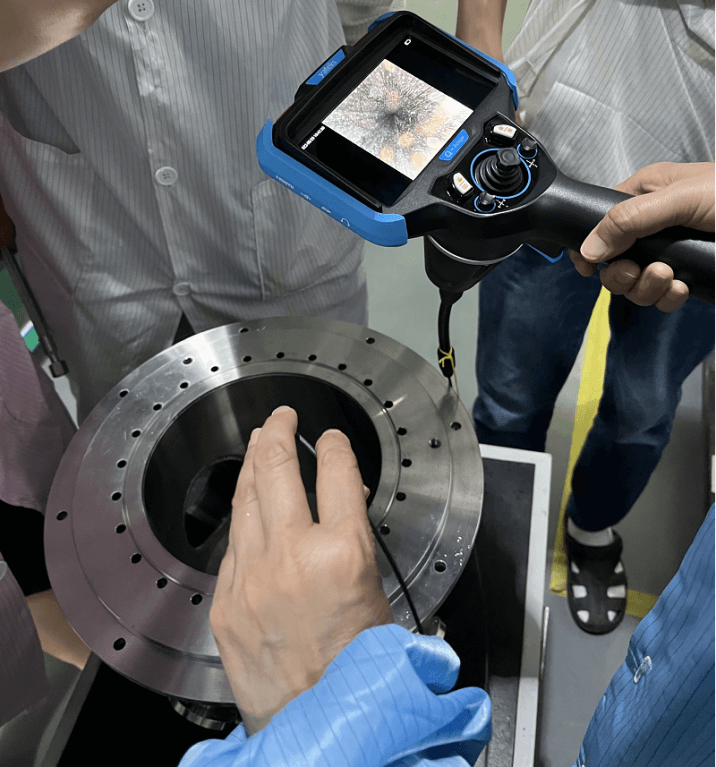

Production or maintenance inspections of bearings can use portable industrial endoscopes. No disassembly is required, and the internal conditions of the bearing can be directly observed. Check its internal wear and potential problems, and take appropriate solutions to reduce the risk.

Let’s share which defects of the bearing can be detected by the portable industrial endoscope:

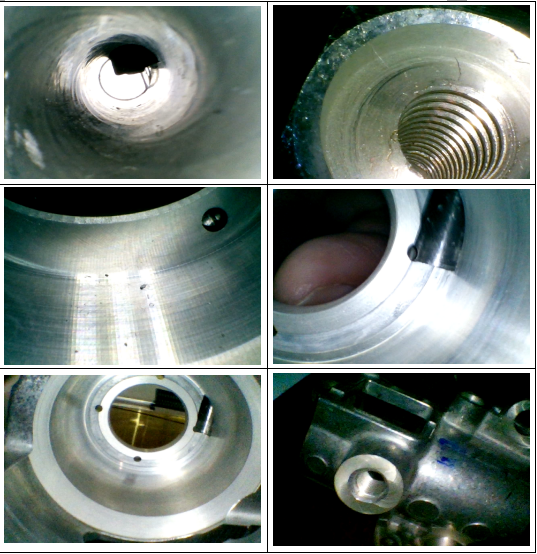

1.Check for cracks

Check for cracks Check whether various raw materials have cracks, forging, heat treatment, grinding and other cracks. To avoid these cracks, the bearing will be broken during the subsequent use and operation of the bearing, so that the service life of the bearing will be affected. More importantly, it affects job security.

2.Check for mechanical scars

Check for mechanical scars You can check for crushing, scratches, bruises, abrasions, etc. Avoiding such defects will lead to poor bearing installation, cause eccentric load and stress concentration, and affect the rotation accuracy and service life of the bearing.

3.Corrosion inspection

Industrial endoscopes can check for defects such as rust, black skin and pitting. Avoid defects from developing into rust, leading to poor installation, early wear and fatigue pollution sources, and even lead to direct scrapping of bearings in the case of severe rust.

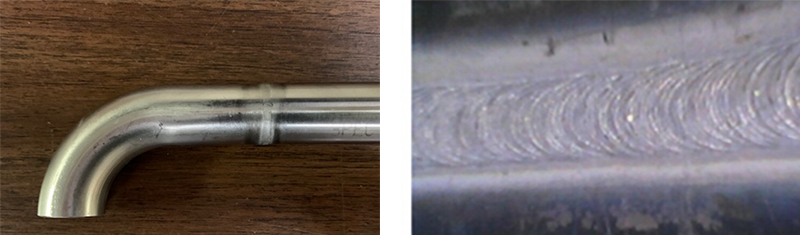

4.Welding quality inspection

Welding quality can use a portable industrial endoscope to observe whether the welding position is correct. Are the solder joints too large or too small? Is there a phenomenon that the rolling elements are stuck due to weak welding or excessive welding? If there is a problem, it will cause a certain amount of noise to the bearing. It will even reduce the rotation accuracy, and even cause the cage to fall apart, resulting in mechanical failures or accidents.

Yateks Industrial Endoscope can solve the above problems. Yateks supplies a variety of endoscopes for different levels of needs,HD image quality, flexible articulation,different diameter cameras,length and camera options for you to select to meet various onsite application needs at cost-effective price.

Our endoscope are designed and made to meet modern demands for safety, efficiency, and precision in the aerospace, power generation, oil & gas, and infrastructure industries.