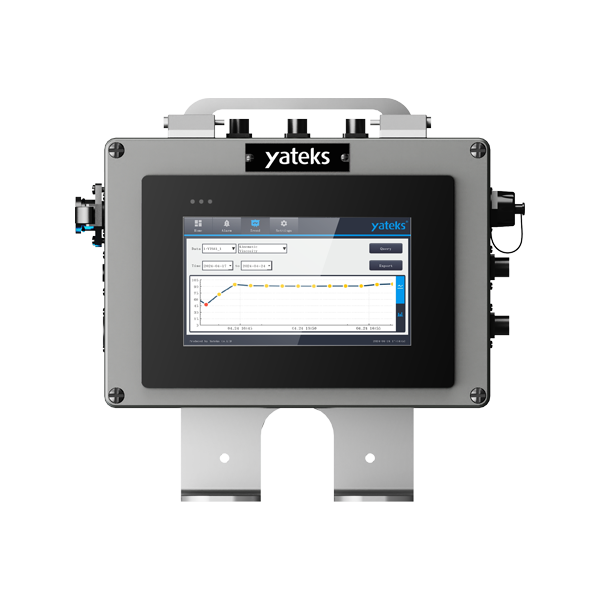

As the maritime industry continues to evolve, the need for advanced technologies that enhance safety and operational efficiency is becoming increasingly important. Yateks’s Online Oil Monitoring System represents a significant innovation in this field, providing ship operators with the tools necessary to maintain optimal performance and safety. Here’s a closer look at why ships need such systems, the problems Yateks can solve, and the benefits for ship engines.

1. Why Do Ships Need an Online Oil Monitoring System?

Ships operate in demanding environments where machinery and systems are constantly subjected to stress, wear, and varying operational conditions. An online monitoring and measurement system is essential for several reasons:

(1)Real-Time Data Access

It provides immediate insights into the condition of oil and lubricants, allowing for timely decision-making.

(2)Preventive Maintenance

By continuously monitoring oil parameters, operators can identify potential issues before they lead to significant failures, reducing the risk of accidents and damage.

(3)Regulatory Compliance:

Many regions have stringent regulations regarding emissions and operational standards. An online monitoring system helps ensure compliance by monitoring fuel quality and oil conditions.

(4)Operational Efficiency:

Efficient oil management helps optimize fuel consumption, leading to cost savings and better environmental performance.

2. What Problems Can Yateks’s Online Oil Monitoring System Solve?

Yateks’s system addresses several critical issues faced by ship operators:

(1)Oil Degradation and Contamination

It detects changes in oil quality due to contamination or degradation, providing alerts that prompt maintenance actions.

(2)Unexpected Equipment Failures

By monitoring key indicators, the system helps prevent sudden equipment failures that can lead to costly downtime and repairs.

(3)Inconsistent Oil Usage

It helps track oil consumption patterns, allowing operators to optimize usage and avoid waste.

(4)Unplanned Maintenance Costs

Early detection of oil-related issues allows for planned maintenance, reducing unplanned repairs and associated costs.

3. What Are the Benefits of the Online Oil Monitoring System for Ship Engines?

The advantages of implementing Yateks’s Online Oil Monitoring System extend beyond mere monitoring and include significant benefits for ship engines, such as:

(1)Enhanced Engine Longevity:

By ensuring optimal oil conditions, the system helps reduce wear and tear on engine components, ultimately extending their lifespan.

(2)Improved Performance:

Consistent monitoring allows for adjustments that optimize engine performance, leading to more efficient operations and lower fuel consumption.

(3)Cost Efficiency:

Reduced maintenance needs and the prevention of major repairs lead to significant savings over time. The system can also reduce fuel costs by ensuring that engines run efficiently.

(4)Data-Driven Decision Making:

The comprehensive data collected enables informed decision-making regarding maintenance schedules and operational practices, leading to better overall management of the vessel.

(5)Environmental Compliance:

By optimizing oil use and reducing emissions, the system helps ships meet environmental regulations and commitments, contributing to sustainability efforts in the shipping industry.

Conclusion

The implementation of Yateks’s Online Oil Monitoring System is a game-changer for the maritime industry. By providing real-time monitoring, addressing key operational challenges, and delivering significant benefits for ship engines, this system enhances both safety and efficiency at sea. As the industry continues to embrace digital transformation, solutions like Yateks’s monitoring system will play a crucial role in shaping the future of maritime operations. If you’re interested in how this technology can benefit your fleet, don’t hesitate to reach out for more information.