Pharmaceutical Plants need cleaning

Clean pipelines in pharmaceutical plants are an important part of the pharmaceutical production process. At present, the sterile clean pipes are made of stainless steel and adopt the most advanced laser welding process.

GMP, FDA certification and pharmaceutical production processes all have extremely stringent requirements on the quality of pipe welds. For example, injection water pipelines, material pipelines, pure steam pipelines, etc., are required to provide good medium conveying environments such as pollution-free, corrosion-resistant, and clean interior walls. This requires production companies and construction units to provide qualified products that meet the specific requirements of the pharmaceutical industry.

The stainless steel tube must be smooth and free of oxidation. Since the thickness of stainless steel thin-walled tubes is less than 3mm, the order of assembly and welding is improper, and the selection of welding process parameters is unreasonable, which may cause welding deformation of the tube sheets, resulting in poor sealing and tube pull-off. If the welding of the construction pipe is slightly inadvertent, serious consequences may occur.

The advantages of borescope inspection used in Pharmaceutical Plants

The industrial borescope is used as a non-destructive test. In order to ensure the quality of pipe welding, industrial endoscopes provide strong support for the inspection of the outer surface of welded parts. Non-destructive testing can be carried out without disassembling or destroying the assembly and stopping the operation of the equipment. Photographing and recording can be performed on the parts inspected for the purpose of monitoring, recording, storing and image analysis of the field of view. inspection report.

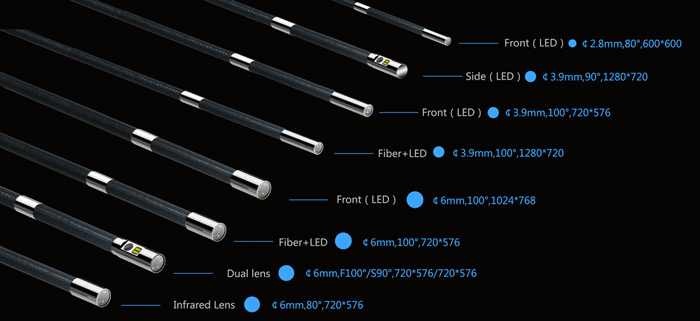

The main function of the industrial endoscope is to detect the inside of the pipe, the instrument and the inside, which are not recognized by the human eye, and mainly check the surface of the pipe and the weld for cracks, white spots, blisters, pores, and slag inclusions. Splashes, scales, pits, paint, and rust on the weld surface of the workpiece should be eliminated before inspection. Due to the complicated environment in which industrial pipe endoscopes are used, it is usually necessary to determine the type of endoscope to be used according to the specific position and requirements of the test object. At least the position, direction, and path of the test should be considered. Complex products often require multiple models. Use with an endoscope.

Yateks P-series High-Resolution Endoscope Camera for pipeline inspection of pharmaceutical equipment:

1. Internal cavity examination. Inspect for surface cracks, peeling, pulling, scratches, pits, bumps, spots, corrosion, etc.

2. Inspection of weld surface defects. Check weld surface cracks, incomplete penetration, and weld leakage.

3. Status check. When certain products (such as worm gear pumps, engines, etc.) work, endoscopic testing is performed according to the items specified in the technical requirements.

4. Excess inspection. Check for residual internal debris, foreign objects, etc. in the inner cavity of the product. This P series borescope design with an 8‐inch ultra clear touch screen, 100,000 LUX brightness, an electronic magnetic rocker which can adjust omnidirectionally for 360°, and its lower price, which helps P Series endoscope 3mm enjoy its superiority. The maintenance and repair of production equipment for pharmaceutical equipment have greatly improved work efficiency and help.

Industrial videoscope is becoming more and more important not only in the pharmaceutical equipment industry and in the pharmaceutical industry, but also in other pipeline welding inspections. The application of endoscopes in pipeline welding detection has made great contributions to the discovery of welding defects affecting the medium conveying environment and how to control these welding defects in the actual production process so that the quality of pipeline welding can be effectively controlled throughout.

Recommend P-series High Resolution Endoscope Camera