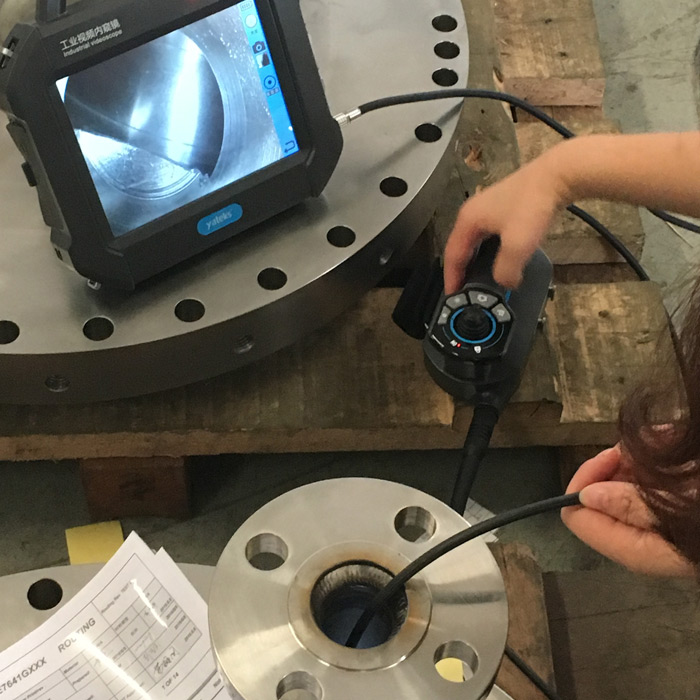

Remote Visual Inspection(RVI) with industrial endoscopes to better restore defects and make effective decisions.

Industrial endoscope, as the name suggests, are places that the human eye cannot see, that is, the inside of the engine body. Therefore, the core technology of industrial endoscopes is the imaging quality and illumination technology of CCD cameras, that is, the position of inspection can be clearly seen in a bright lighting environment. There is basically no difference in the quality of high-end industrial endoscopic imaging. There are two different technologies in lighting technology, namely, the rear lighting technology and the front lighting technology.

What is the front lighting technology and the rear lighting technology?

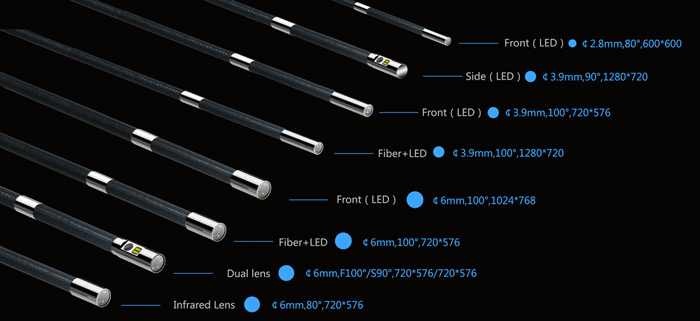

Pre-illumination technology: LED particles of illumination source are mounted on the lens surface with a diameter of only 6mm, and the position of the central camera must be avoided. Therefore, the size, power, and quantity of LED particles placed are extremely limited. The total power of the 6 LEDs is only 3W. The electrical contacts on the front of the probe are powered to illuminate the illumination source.

Rear lighting technology: The LED light particles of the illumination source are placed inside the host, and the light is transmitted from the inside of the host to the light exit of the front end of the probe through the low-loss light guiding optical fiber. Since the LED lighting particles are not limited by space, the large volume and high power can be placed. The light source, Germany Visa uses a 6W LED lighting source.

Yateks endoscope fiber-optic LED lighting is not limited by the installation space. The brightness of the illumination source can reach more than 100,000 LUX. Because the illumination source is placed inside the host, during the use of the endoscope, the light source is not subject to the collision, and there may be almost no physical trauma. Only normal service life loss. The front lighting is limited by the installation space, and only a small particle LED light source can be placed. The contrasting light can be found to be weak. The brightness of the Yateks videoscope LED illumination is 24,000, but the illumination source is placed at the front end of the probe. During the use of the speculum, it will continuously collide with the detected object, and its physical trauma will cause the brightness of the light source to be excessively lost.

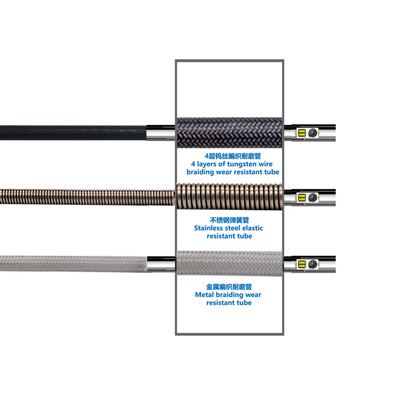

The saying that “post-illumination will cause damage to the illumination due to damage to the probe” is in the concept of stealing. There are not only optical fibers in the probe line, but also guide wires and channels, camera signal lines, such as probe damage. All should be damaged, damage the most critical camera signal line. Therefore, the first-line brand endoscope manufacturer will design the steel stranded frame and the double-layer tungsten wire wrapped skin in the probe line to protect the probe as a whole, which is the most effective to reduce the damage of the probe and internal components.

Based on the above comparisons, it can be clearly seen that front-end lighting technology as a low-cost and immature technology is no longer suitable for industrial endoscopes operating in demanding environments, and it is indeed in the past. Lighting technology brings a heavy maintenance burden to the user department and delays the quality of work. Just as the trend of technology development needs, the world’s high-end industrial endoscope brand has basically adopted the LED lighting source post-technology.

Rear fiber optic lighting technology is a new generation of industrial endoscope lighting technology, which improves illumination brightness, protects illumination source, and reduces the risk of damage to endoscope core components. It is the most suitable lighting technology in the field of industrial endoscopes.

Yateks 1-3m Rear LED lighting

It’s time to experience an phenomenal degree of top quality and also performance in a manner you never thought possible.