-

Why do I need an online oil monitoring system and what are the key areas to monitor?

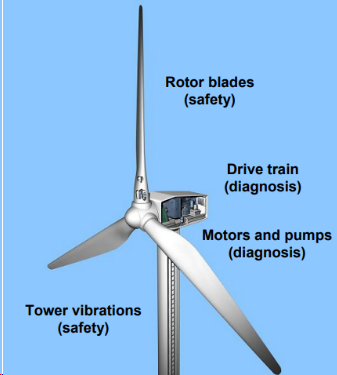

In the wind power industry, the stable operation of equipment is critical to power generation efficiency. An online fluid monitoring system monitors the status of the fluid in real time to ensure that the equipment is operating under optimal conditions. Key monitoring areas include:

Transmission: monitoring the condition of the lubricant, including viscosity, contaminants and wear particles.

Generators: Monitoring the quality of the insulating oil to ensure the stability of the electrical system.

Lubrication systems: Monitor the lubricant in real time to prevent friction and wear due to fluid deterioration.

-

What are the risks of not monitoring fluids?

If oil monitoring is not performed, the following risks will be faced:

Equipment failure: Contamination or deterioration in the fluid cannot be detected in time, resulting in unstable equipment operation and increasing the risk of failure.

Loss of downtime: Sudden failures may lead to equipment downtime, affecting power generation capacity and causing financial losses.

High Repair Costs: Unmonitored problems can lead to more serious equipment damage, which can be expensive to repair.

Safety hazards: Equipment failure may lead to safety accidents, posing a threat to employees and the environment.

-

What monitoring solutions does Yateks offer to its customers?

Yateks offers a comprehensive range of online oil monitoring solutions, specifically including:

Real-time monitoring system: monitoring the temperature, viscosity, moisture, wear particles and contaminant content of the fluid in real time through sensors.

Data analysis platform: Provide data collection, storage and analysis services to help customers develop scientific maintenance plans.

Alarm mechanism: Once abnormal conditions are monitored, the system will quickly issue an alarm to facilitate customers’ quick response.

Customized service: Provide personalized monitoring solutions and technical support according to customer needs.

-

What are the benefits and economic benefits of online monitoring?

The implementation of an online fluid monitoring system will bring significant benefits and economic benefits:

Improve equipment reliability: Ensure efficient operation of equipment and enhance power generation capacity through timely monitoring and maintenance.

Reduced maintenance costs: Reducing the need for sudden breakdowns and repairs reduces overall operating costs.

Extend equipment life: Scientific monitoring and maintenance strategies help extend equipment life cycles and reduce replacement frequency.

Optimize resource allocation: Through data analysis, rationally arrange maintenance and resource usage to improve management efficiency.

Enhance safety: Effective monitoring of fluid quality reduces safety risks and protects employees and the environment.