The use of lubricant online monitoring device in petrochemical equipment is crucial to ensure the stable operation of the equipment, prevent potential failures and optimise the maintenance strategy.

1. Why is the lubricant online monitoring device in the petrochemical equipment is important?

(1) The operation of petrochemical equipment often depends on high-quality lubricant to ensure its normal operation. The state of the lubricant directly affects the performance, efficiency and life of the equipment. Therefore, real-time monitoring of lubricating oil is particularly important. Lubricant online monitoring device through the installation of sensors on the equipment, can real-time access to the key parameters of the lubricant, such as viscosity, moisture content, impurities and particles.

(2) Through real-time monitoring of these parameters, the device can detect abnormal changes in the lubricant in time. For example, when the moisture content in the lubricant exceeds the standard or the impurities increase, the device will immediately issue an alarm to remind the operator to take appropriate measures. This helps to avoid equipment failures and downtime caused by lubricant problems and reduce production losses.

(3) The lubricant online monitoring device can also predict potential equipment failures. Through continuous monitoring and analysis of the lubricant, the device is able to identify the trend of lubricant performance decline or abnormal fluctuations, so as to predict the possible failure of the equipment. This provides a basis for enterprises to repair or replace the lubricant in advance, which helps to avoid the occurrence of equipment failure and reduce maintenance costs.

(4) In the maintenance and management of petrochemical equipment, lubricant online monitoring device also plays an important role. Through real-time data monitoring and analysis, companies can more accurately understand the operating conditions of the equipment and the performance status of the lubricant, so as to develop a more reasonable maintenance plan. This not only reduces maintenance costs, but also improves the reliability and service life of the equipment.

The application of lubricant online monitoring device needs to be combined with the actual situation of the enterprise. Different petrochemical equipment, different operating environments and different types of lubricants, need to choose the appropriate monitoring device and monitoring programme. At the same time, the operator also needs to have a certain degree of professional knowledge and operational experience to ensure the accuracy and reliability of the monitoring data.

2. What is the petrochemical lubricant online monitoring device?

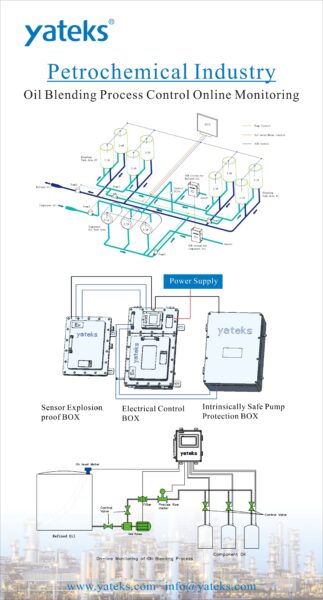

Petrochemical lubricant online monitoring device is a kind of equipment specially used for real-time monitoring of lubricant status in petrochemical equipment. By integrating a variety of sensors and monitoring technology, it can obtain the key parameters of the lubricant in real time, such as temperature, pressure, viscosity, moisture content, acid value, particulate matter, etc., in order to assess the quality of the lubricant, its performance and the health of the equipment.

The main functions of the device include:

(1)Real-time monitoring and assessment

Through continuous monitoring of the lubricant, the device is able to understand in real time the physical and chemical properties of the lubricant, as well as the working status of the equipment, so as to ensure the safe and stable operation of the equipment.

(2)Fault warning and prevention

Through the analysis of lubricant parameters, the device is able to predict potential failures, such as oil contamination, excessive moisture, viscosity changes, etc., so that maintenance measures can be taken in advance to avoid equipment downtime or damage.

(3)Optimise maintenance strategy

Based on real-time monitoring data, the device can help enterprises to develop a more reasonable and efficient maintenance programme, reduce maintenance costs, improve the operational efficiency and service life of equipment.

Petrochemical lubricant online monitoring device also has a remote monitoring function, the operator can monitor the liquid condition through remote means, without the need to visit the scene, thus improving the efficiency of operation and maintenance. Petrochemical lubricant online monitoring devices play an important role in ensuring equipment safety, preventing failures, optimising maintenance, etc., and are an indispensable tool in the petrochemical industry. Yateks has rich experience in this area, if you have any needs, you can contact us.