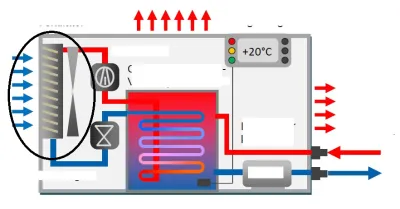

A heat exchanger is a device that transfers heat between fluids, also known as a heat exchanger. This device is used in quite a few application scenarios or processes. Like water heaters in homes. In addition, the industrial sector uses more, such as: fossil fuel boilers, nuclear steam generators, steam condensers, cooling towers, and some heat recovery devices. Covering manufacturing, power industry, pharmaceuticals and many other industries, especially the petrochemical industry. The following diagram shows the working principle of a heat exchanger.

What problems can occur with heat exchangers?

Heat exchangers vary greatly in size, with the likes of the power generation industry usually using larger heat exchangers. Also tube heat exchangers are the most common form. Under the influence of constantly moving liquids and frequently changing temperatures, these tubes are prone to wear, contamination, coating breakage and other defects on the inside. In particular, scaling builds up on the inside of the tube wall, which over time reduces the heat transfer capacity within the heat exchanger, affecting its performance and possibly even leading to pressure problems and dangerous accidents.

What can industrial borescopes be used to inspecti on heat exchangers?

- Visual inspection of the internal components such as tubes, fins, and internal structures for signs of corrosion, scaling, fouling, or blockages.

- Detection of leaks or cracks in the tubing or welds.

- Assessment of the overall condition of the heat exchanger to determine if it requires cleaning, maintenance, or repairs.

- Monitoring of the heat exchanger performance by inspecting the internal components for any signs of wear or deterioration.

- Documentation and recording of the inspection process for quality control and compliance purposes.

How to choose the right industrial borescope to use in the heat exchanger is inspection use?

The industrial endoscope is a multidisciplinary universal tool. There are various types, the main application for heat exchange inspection is video endoscopy, which consists of: control panel, probe line, camera (customarily called probe together with the probe line), display, light source, battery and so on. Its characteristic is to expand the ability of the human eye through the imaging technology, so as to achieve a deeper, even across the obstacles of visual inspection. In the heat exchanger inspection applications are mostly used in an integrated design – handheld borescope, operation is more convenient, and is not affected by the complexity of the working conditions.

When using a handheld borescope to inspect a heat exchanger, the operator will use one hand to probe the tube and camera deep into the interior of the pipe to be inspected, and then control the joystick on the borescope’s control panel with the other hand, so that the camera can rotate and move in different directions (also known as guided control), and through the display screen to observe the interior of the heat exchanger, and quickly and accurately find oxidation, sludge, rust, dust particles, biological deposits, erosion, corrosion, and caking. The heat exchanger is then viewed through a display that quickly and accurately detects oxidation, sludge, rust, dust particles, biological deposits, erosion, corrosion and scaling. After the heat exchanger is maintained or cleaned for the problems found, the endoscope can also be used to view the results.

During the endoscopic inspection, the camera guidance function is of great significance for a comprehensive inspection. For large heat exchangers, the pipeline is often long, in this case, if the electric guide can not meet the requirements of deep area inspection, you can choose the pneumatic guide. Yateks’s industrial borescope technology is flexible in changing probes, so according to the heat exchanger’s inspection requirements, it can realise longer-distance sensitive guiding, and help efficient and comprehensive inspection of the heat exchanger.