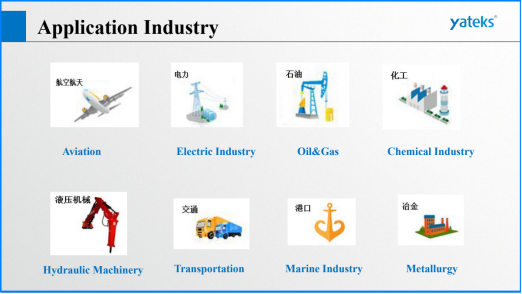

At Yateks oil condition sensor , we have solid experience of the various conditions and requirements of many different industries regarding condition-based maintenance. However, they all have one thing in common: the need for the earliest possible warning of machine faults. Find out how we meet the needs of various industries and how we help our customers minimize unplanned downtime and secure production!

For instance, the business sectors including power, logistics, mining, and manufacturing deploy oil-dependent machines, vehicles that are equipped with gearboxes, engines, hydraulics, and transformers which require regular health and status inspections in order to operate at their maximum efficiency.

Moreover, This instance becomes a critical factor to consider as these sectors operate in extreme and often harsh climatic conditions such as humid mine sites, artic natural gas processing plants among others with oil condition degrading over time and losses its.

Although traditional oil analysis techniques such as laboratory testing provide an extensive view of oil condition and machinery health yet it does come with drawbacks such as high upfront cost, time delay, and occasionally malfunctioning, with critical machine potentially cost the organizations thousands of dollars per hour, organization are looking to invest reliable in-line oil analysis solutions such as Oil Condition Monitoring.

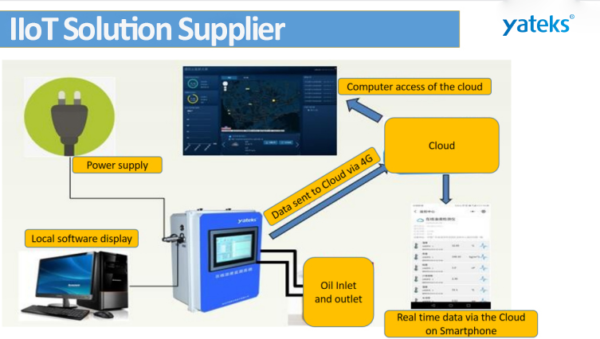

Yateks online monitoring system can monitor the physical and chemical indicators, pollution degree and wear particles of equipment lubricating oil in real time. Among them, the physical and chemical indicators include oil viscosity, density, dielectric constant, temperature, micro water, and water content; pollution degree refers to the pollution of particles in the oil; water content refers to the water activity and saturation in the oil. Wear particles are the occurrence of particles in the oil that result from wear. We have rich experience in different application fields, if you have needs, you can contact us in time.