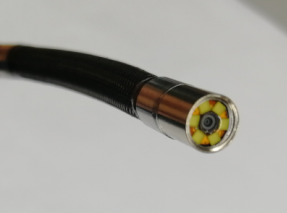

Industrial endoscopes, just as its name implies, are the device to inspect those narrow areas which human eyes/views can’t reach. To inspect and see the target position clearly, enough light is quite necessary and important. Therefore, its matched illumination system must be good enough to satisfy the illuminating demands for dark areas in different degree.

Currently, there are two common illumination technologies for industrial videoscopes: one type is “LED illumination only”, another type is “fiber + LED illumination combined”. What type of illumination way should the customer choose for his application? A brief introduction and comparison for these two types should be clarified. Yateks has both solution options for industrial borescopes available!

Comparison:

| Items | Only front LED illumination | Fiber + LED illumination |

| Packaging Method | Several LEDs around the camera on the tip surface | LED light source in the base unit, using the optical fiber to guide the light |

| LED power | 6 small LEDs, in limited size and space, smaller power | One big LED, no size limits, bigger power |

| Brightness loss | Light source is in the tip part, which may be physically impacted/ scratched while inspection, causing brightness loss. | Light source is in the base unit, which won’t be damaged during inspection. |

| Security grade under water/oil | Light source and front electric contact is not totally sealed condition; under water/oil, once contacted conductor material, it will cause short circuit of the whole system. | It will have no influence on the light source under water/oil environment, because the light source is in the base unit. |

| Influence on CMOS sensor

/camera |

Light source in the front tip will get hot while working, which is close to camera; heat over camera will speed up its aging progress. | Light source is in the base unit, which will not cause heat influence to the camera. |

| Repair and its cost | If the LED is faulty, the whole camera module needs to be replaced together because the LED is integrated/ packaged into the whole front camera module. | If the LED is faulty, only the LED in the base unit needs to be replaced;

If the optical fiber is damaged when outer force pinches the insertion tube, the optical fiber needs to be replaced. |

| Advantage | 1) Lower cost on for new unit;

2) shorter manufacturing time |

1) Ultra high brightness can satisfy high demands for applications;

2) Nearly no heat over the tip; 3) Lower repair cost if only the LED is faulty; |

| Disadvantage | 1) Lower brightness due to limited space for small LED;

2) Heat on the tip may affect the camera life expectancy and performance; 3) When only the LED is faulty, the whole integrated camera module needs to be replaced. |

1) Higher cost because the optical fiber is higher cost and the assembly for optical fiber is more time-consuming and high demands.

2) High standards of optical completeness |