Ferrography is a technique in which metal particles in oil are separated by magnetic force and analyzed. There are two main types of iron ferrography: one is a Direct-reading ferrography. Direct-reading ferrography is a more mathematical approach to ferrography. Essentially, the buildup on the glass slide is measured by shining a light across the slide. The blockage of the light by the buildup of particles is then used, over time, to calculate an average. An increase in blockage indicates higher amounts of machine wear. This direct reading spectrometer technology is relatively backward and gradually eliminated.

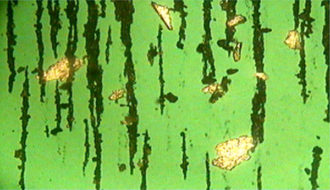

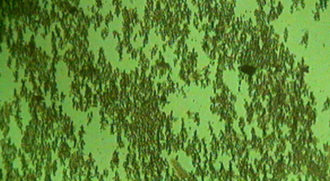

The other is the analytical ferrography, it works through magnetic separation of contaminant particles and professional analysis of the particles. A sample of the machine’s lubricating oil is taken and diluted, then run across a glass slide. This glass slide is then placed on a magnetic cylinder that attracts the contaminants. Non-magnetic contaminants remain distributed across the slide from the wash. These contaminants are then washed, to remove excess oil, heated to 600 °F for two minutes, and the slide is analyzed under a microscope. After analysis, the particles will be ranked according to size. Particles over 30 microns in size are considered “abnormal” and indicate severe wear. Analytical Ferrography is an effective wear debris analysis tool that is expensive due to the need for specialized and complex instruments.

YTF-8 Dual Slide Analytical Ferrography for sale

It works quite well for me

Like!! Great article post.Really thank you! Really Cool.