The turbine lubricating oil system extracts the lubricating oil from the oil tank through the oil pump, and after filtering and cooling, distributes it to all parts of the engine to form a uniform oil film to reduce friction and cool the moving parts. The lubricating oil is returned to the oil tank after the formation of oil film to achieve recycling. The system is equipped with monitoring equipment to ensure that oil pressure, temperature and other parameters are within the appropriate range. This process ensures smooth operation inside the turbine and prolongs the service life of mechanical parts.

I.Composition of turbine lubricating oil system

The turbine lubricating oil system is composed of oil tank, oil pump, oil filter, cooler, regulator, distributor, injector, and lubricating oil monitoring device. The details are as follows:

1.Oil tank

The container for storing lubricating oil. The oil tank is usually located at the bottom of the generator set or turbine body for storing lubricating oil and may be equipped with an oil level gauge, thermometer and filter.

2.Oil pump

Responsible for the lubricating oil from the oil tank and transported to the need for lubrication parts, to ensure that all parts of the engine can get enough lubrication.

3.Oil filter

Used to filter impurities and contaminants in the lubricating oil to prevent them from entering the engine and keep the oil clean.

4.Cooler

Some systems will include a lubricant cooler, used to reduce the temperature of the lubricant, to ensure the normal operation of the system and extend the service life of the lubricant.

5.Regulator

Used to maintain the lubricant pressure in the system within the appropriate range. It ensures that the engine is adequately lubricated under different loads and operating conditions.

6.Distributor

Directs the lubricant to the various parts of the engine that need lubrication, such as bearings, gears and other moving parts.

7.Injector

Some systems use injectors to spray lubricant directly onto the surfaces of high-temperature or high-friction parts to reduce friction and cool those parts.

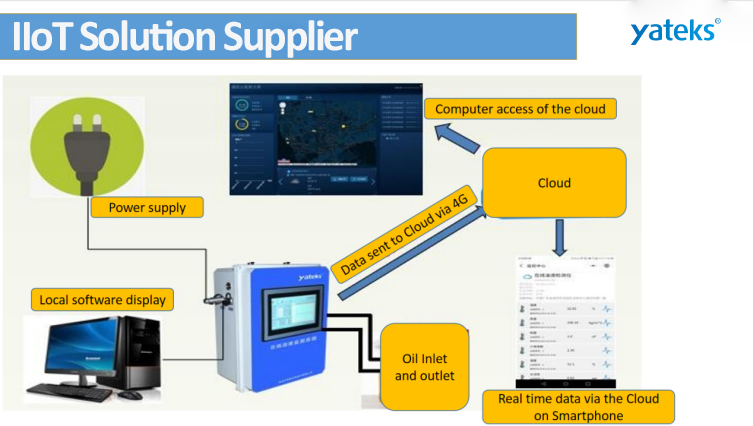

Lubricating oil online monitoring device is used to monitor the quality, viscosity, moisture, temperature and pressure of lubricating oil online to ensure the normal operation of the system.

II. Role of turbine lubricating oil system

Turbine lubricating oil system plays a key role in the normal operation of the turbine, which is mainly reflected as follows:

1.Reduce the friction between contact surfaces of components

Various moving parts inside the turbine, such as bearings and gears, will generate friction during high-speed rotation and movement. The lubricant forms a film on the surface of these parts to reduce the friction, thus reducing the energy loss, improving the efficiency and prolonging the life of the parts.

2.Cooling parts temperature

Lubricating oil not only lubricates, but also plays a cooling role. In the high-temperature environment of the turbine, by taking away the heat from the surface of the components, the lubricant helps to maintain the proper working temperature, prevent overheating of the components, and improve the reliability and stability of the system.

3.Cleaning function

By flowing inside the turbine, the lubricating oil can take away impurities, particles and pollutants and filter them through the oil filter to keep the lubrication system clean. This helps to prevent wear and corrosion of component surfaces.

4. Provide sealing effect

The film formed by the lubricant between moving parts not only reduces friction, but also helps to form a seal to prevent gases and contaminants from entering the mechanical parts, maintaining the integrity and performance of the parts.

5. Anti-corrosion

Lubricating oil usually contains anti-corrosion and anti-oxidation additives to prevent metal parts from corrosion and oxidation, extending the service life of the turbine.

6. Pressure regulation and balancing

The regulator in the lubricant system maintains proper oil pressure to ensure that all parts of the system are adequately lubricated. This is crucial to balancing the performance and reliability of the system.

7. Improve equipment efficiency

By reducing friction, lowering temperature and maintaining cleanliness, the lubricating oil system helps to improve the overall efficiency of the turbine, reduce energy loss and improve energy utilisation.

The role of the lubricating oil system in the turbine is to ensure that each mechanical component can maintain adequate lubrication while operating at high speed, thus improving the reliability, stability and life of the system.

III. Working Principle of Turbine Lubricating Oil System

The working principle of the turbine lubricating oil system is to ensure that the lubricating oil forms a uniform oil film inside the turbine to reduce the friction between the parts, cool the moving parts, and remove the pollutants, so as to guarantee the normal operation and prolong the life of the turbine.

1.Oil pump work

Firstly, the lubricating oil will be extracted from the oil tank by the oil pump and transported to each part that needs lubrication in the engine. The oil pump is responsible for maintaining the oil pressure in the system to ensure that enough lubricant can flow to the various parts of the engine.

2.Oil filter filtration

The oil pump extracted lubricating oil first through the oil filter, which is to remove impurities, particles and other contaminants in the oil. The filtered clean oil continues to flow to the engine interior.

Oil Cooling: In some systems, the lubricating oil may pass through a cooler to lower its temperature. Cooling helps prevent the lubricant from losing its lubricating properties in high temperature environments and also helps cool moving parts to maintain proper operating temperatures.

3.Oil Distribution

After filtration and possible cooling, the lubricating oil is directed to different parts of the engine interior, such as bearings, gears, sliding surfaces, and so on. This process is accomplished by a network of distributors and pipes.

4. Formation of oil film

The lubricant forms a film on the surfaces of moving parts, which helps to reduce friction and wear between the parts. The oil film also helps to form a seal that prevents gases and impurities from entering the engine.

5. Oil Recovery

Once the oil film is formed, the lubricant flows back into the tank and rejoins the cycle. This process ensures that the lubricant is continuously recycled and that the quality of the oil remains at the right level.

6. Monitoring and regulation

Lube oil systems are usually equipped with monitoring equipment for real-time monitoring of parameters such as temperature, pressure and quality of the lubricant. Regulators and other regulating devices ensure that the oil pressure in the system is maintained within a suitable range.

The lubricating oil system of the turbine realizes the circulation, filtration, cooling, distribution and monitoring of the lubricating oil through the synergistic action of the oil pump, oil filter, cooler, distributor and other components, so as to ensure that the various moving parts can be properly lubricated, thus guaranteeing the normal operation of the turbine.

1.Workflow of turbine lubricating oil system

The workflow of a turbine lubricant system can be divided into the following main steps, which ensure the circulation, filtration, cooling, distribution and monitoring of the lubricant in the whole system. However, the specific system design may vary depending on the manufacturer and model.

2. Lubricant Storage and Supply

The work of the turbine lubricating oil system begins in the oil tank, where sufficient lubricating oil is stored. At the beginning, the oil pump is activated to draw the lubricating oil from the tank.

3. Pressure regulation and filtration

The oil pump feeds the lubricant into the system and passes through the regulator to maintain proper oil pressure. Before entering the system, the oil passes through an oil filter, a step designed to remove impurities and particles from the oil.

4. Lubricant Cooling

Some systems may include a lubricant cooler. The lubricating oil passes through the cooler, lowering the temperature and ensuring that the lubricating oil can still work effectively in a hot environment. The cooler usually reduces the lubricant temperature through the cooling medium of the turbine or an additional cooling system.

5. Lubricating oil distribution

Filtered and cooled lubricating oil is directed to different parts of the engine interior, such as bearings, gears, sliding surfaces, etc. The lubricating oil is distributed through a network of distributors and pipes. A network of distributors and pipework is responsible for transferring the oil to the various parts along a designed path.

6. Formation of oil film

The lubricant forms a uniform film of oil on the surface of moving parts. This film helps to reduce friction, cool the surfaces of the parts, and create effective lubrication.

7. Lubricant Recycling

The lubricated oil flows back into the tank along a designed recycling path. This ensures that the lubricant can be recycled and that some heat and contaminants are carried away during the return process.

8. System monitoring and control

The lubricant system is equipped with various monitoring devices for real-time monitoring of parameters such as lubricant temperature, pressure, flow and quality. Regulators and other regulating devices ensure that the oil pressure and other key parameters in the system are maintained within appropriate limits.

The goal of the entire process is to ensure that the lubricant provides good lubrication inside the turbine, reduces friction between components, maintains proper temperatures, removes contaminants, and guarantees the reliability and longevity of the system.

If you need:Turbine lubricating oil system monitoring, please contact us at Yateks. Professional for more than 20 years to provide users with oil condition monitoring solutions.