This article starts with the difficulties in the maintenance and inspection of automobile gearbox assembly, and introduces the solution of industrial endoscope for visual inspection of automobile gearbox assembly and the application of industrial endoscope in the inspection of automobile gearbox assembly.

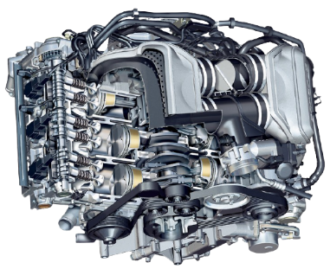

As one of the five major assemblies of a car, the gearbox (also known as the transmission) plays a major role: changing the transmission ratio, controlling reverse driving, and switching control such as engine starting and shifting. It is often necessary to check the gearbox when the vehicle condition is abnormal. Due to the assembly construction, it is difficult to see its internal components (gears, clutches, etc.) through direct visual inspection. Therefore, it is often disassembled and then inspected one by one, or the entire assembly is directly replaced. Disassembling the gearbox for inspection is a dry overhaul, which is not only time-consuming and labor-intensive, but such an overhaul will affect the secondary sale of the vehicle, especially uncertain faults. In some cases, this approach is too aggressive. As for the overall replacement of the assembly, it seems trouble-free and quick, but if the overall replacement is only because of individual components or some minor problems, it is not economically cost-effective for the car owner. These problems are all due to the inability to detect the internal situation in situ, and endoscopic detection technology can improve this dilemma.

Automobile gearbox assembly visual inspection industrial endoscope solution Detection object: automobile gearbox;

Detection reason: The vehicle condition is abnormal, and it is necessary to investigate the internal condition of the gearbox;

Detection tool: industrial endoscope, specifically, fiber optic endoscope or video endoscope can be used:

Operation method: implement disassembly-free detection. Insert the endoscope insertion tube or probe from the oil filling hole, air hole or power take-off box hole, and visually observe the real-time gearbox image on the display screen of the handheld device to check whether the sound detection gear is damaged or whether the synchronizer is damaged , the working condition of the automatic transmission clutch, and the position of the shift fork, etc., and the oil quantity and oil quality of the transmission can also be observed;

Detection conclusion: According to the observed conditions, it is possible to determine whether there is a fault inside the gearbox, and locate the faulty parts and the cause, so that a more reasonable decision can be made: decide whether to disassemble the transmission, clean the transmission, or add lubricating oil The problem can be solved by waiting for the maintenance method, which saves time and effort as a whole, and even the maintenance and replacement are more targeted. The application of industrial endoscopes in the inspection of automobile gearbox assemblies is introduced. A variety of industrial endoscopes can be used for specific inspections, especially fiber optic endoscopes and industrial video endoscopes, because the lighting is bright, and the slender insertion tube part can be bent, which is convenient for passing through the complex environment inside the gearbox , In addition, the guiding ability of the front end also helps to quickly and comprehensively check the gearbox.