Foreword: How do you usually wash your cup? Washing with water? Scrubbing with a dishcloth? Or after washing, check the cleanliness repeatedly until you are satisfied?

Today, I have encountered this problem. As a foreign trade assistant who has just entered Yateks, I am faced with a variety of tests. If I don’t pay attention, I will be seen by my predecessors.

Let me first talk about the passing of things. German customer Johann arrived at the company at 9:00 this morning. By convention, I should prepare a cup of tea for him in advance. The first is to wash the cup. For the first time, I rinsed it directly with water, and I thought it was washed well. General Zheng said that “the tea stain remains on the inner wall of the cup and needs to be rewashed.” The second time, I carefully scrubbed it with a dishcloth but left a small dirty spot on the cup. “Rework” for the third time, qualified. I realized that “For this simple and daily wash of the cup, there are still so many things to learn from!”

So, looking at the overall situation of Yateks, I can’t help but think of such a question – is the quality awareness of our employees really so rigorous? This is not the case. Our products are in strict accordance with the IOS quality system to supervise the entire process and quality; in addition to quality control, we also have CE (European Safety Certification) and RoHS Certificate (Environmental Certification). Since our certification system is so completed, why do we still need the maintenance department?

Our quality department has also been rethinking this issue and putting it into action. We regularly train our employees on quality awareness. We check the quality of our products over and over again. However, do we really try our best? In this world, the most difficult thing is to “do the best of a small thing instead of making a mistake.” The products we sell are exported to dozens of countries and regions, and we must ensure that each product we make is of the best quality, which requires us to cooperate with each department in every stage of production.

For the quality department, as the quality control department, it should take on the responsibility of comprehensively improving product quality. The “Zero Defect Theory” places special emphasis on preventive system control and process control, requiring that things be done correctly the first time so that the product meets the customer’s commitment requirements. The quality department can carry out quality management activities such as “zero defect movement” to improve the sense of responsibility of all employees for product quality and business quality, thus ensuring product quality and work efficiency.

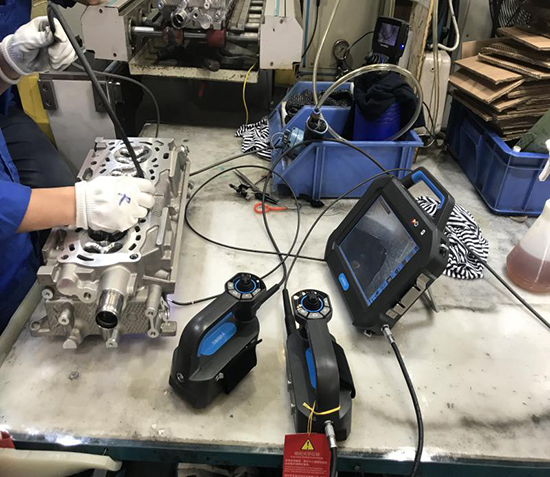

Yateks specializes in endoscope manufacturing and all products are highly praised overseas. After 20-years development, our products have gradually become mature. More than 20 invention patents, gradually occupying the competitive advantage of the market, which makes us more professional. If we work harder on the details, the future is limitless!

As the saying goes, “The details determine success or failure.” This is true. Everything should improve efficiency on the basis of ensuring quality problems, and must not be too hasty! The quality problem is not only a matter of the quality department but also a good habit that every member of Yateks must root into the subconscious mind!