1. ultra-clear, very fine probe.

The ultra-clear picture, for example: more than 2 million pixels, easier to find tiny defects; the thinner the probe, easier to insert into narrow gaps or cavities.

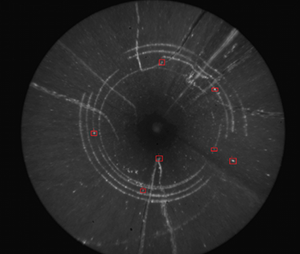

2. Automatic identification and analysis technology.

Various types of metal or non-metal parts or pipeline internal surface defects are important maintenance indicators and judgment basis for various types of equipment, ordinary industrial endoscope internal visual inspection although manual detection can be carried out, but the efficiency is relatively low, the ability of manual identification of defects there are errors and standards are not uniform will also often cause defects missed detection occurs. The use of automatic detection and defect recognition technology based on deep learning, not only can greatly improve the efficiency of detection, reduce the operator’s labor intensity, but also to ensure that the ability to identify defects without interference from the operator.

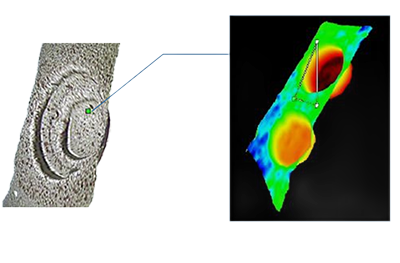

3, three-dimensional display; through the use of 3D models, the shape and internal complex structure of the measurement target can be clearly seen.

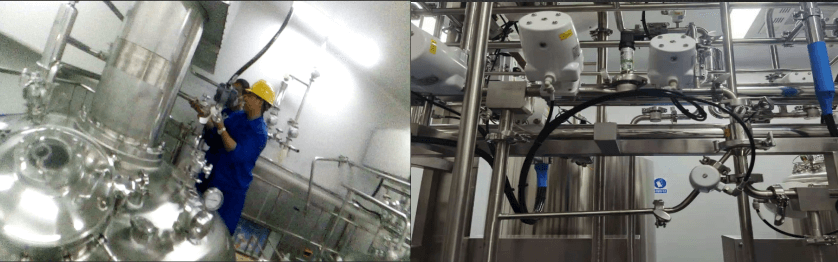

4、In-situ endoscopic repair

In-situ endoscopic repair that is, under the condition of not disassembling, such as the grinding of the blade rolled edge, the cleaning of carbon and the cleaning of small debris in the engine. In civil aviation field maintenance, especially in military aircraft rapid repair, in-situ endoscopic repair can greatly save time and cost, the application value is very high.

This article was first published on the official website of Shenzhen Yateks Co., Ltd, Yateks, a national high-tech enterprise and a well-known brand in Shenzhen, 18 years of industrial endoscope and oil analyzer R & D, production industry experience, the world’s top 500 designated cooperation suppliers. If you want to know more products, please send email to [email protected]