In the aviation industry, aircraft safety is of paramount importance. Even the slightest component failure can lead to severe consequences. This makes aviation inspection work require precision, efficiency, and comprehensiveness. With its unique design and powerful functions, Yateks industrial Realta 3D measurement endoscope has become an indispensable assistant in aviation inspection, playing a crucial role in ensuring flight safety.

Introduction of Yateks Realta 3D measurement industrial borescope.

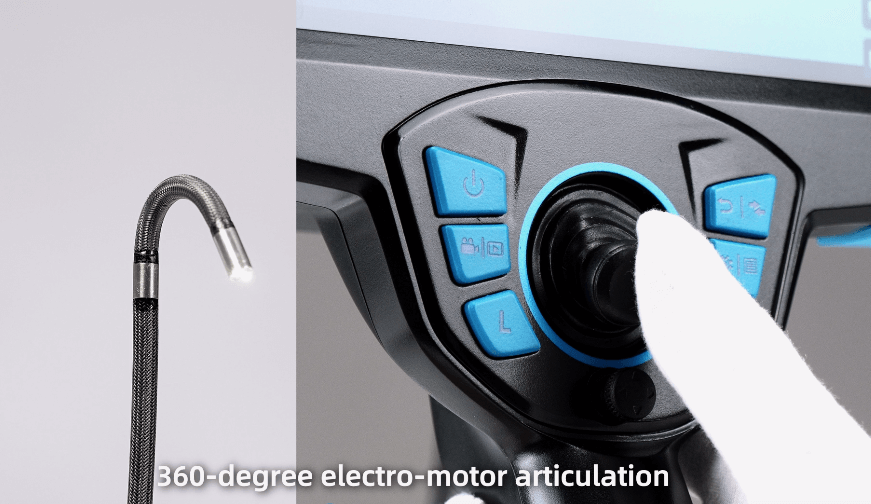

The Realta series features a 7″ IPS HD LCD screen with a resolution of up to 1920 * 1200, offering dual functionality with both touch and button controls for fast and easy operation. It incorporates Yateks patented technology and utilizes self-developed graphic processor technology, enhancing image and video response speed and resulting in a clearer and more detailed presentation of image. The probe allows for 360° omni-directional rotation, equipped with overload protection and automatic locking&resetting capabilities, enabling long-distance image transmission for deeper channel detection. The instrument primarily consists of four components: the camera module, insertion tube, host, and operating handle. This innovative non-destructive flaw detection instrument integrates optics, precision machinery, electro-mechanics, electronic technology, and microscopic camera technology. It is commonly used to detect internal surface defects that cannot be seen by the naked eye.

The advantages of Yateks industrial endoscope in the field of aviation inspection

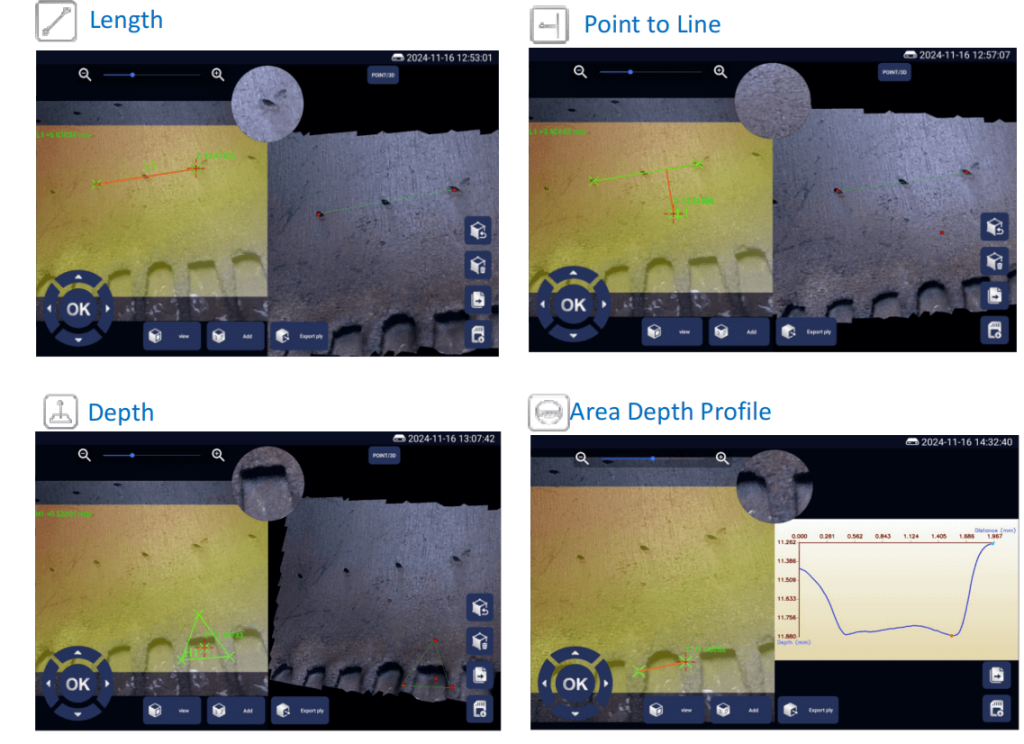

1.Quick Capture and Measurement&Fast Point Cloud Generation

Advanced processing technology and precise measurement performance. Thanks to the advanced processing technology, the system can quickly generate point cloud results within 6 seconds, meeting the needs of high – efficiency inspection.

It supports ultra – close measurements as short as 4mm (depending on the camera’s depth of field), is specifically designed for precision inspection scenarios, and can conduct close – range and high – precision analysis of small components.

Stable and accurate real-time depth measurement – time depth measurement capabilities The system has stable and accurate real – time depth measurement functions, can generate dense point cloud data containing more than 700,000 points, and supports data export for further analysis. The measurement coverage can reach 80% of the field – of – view area, maximizing the measurable area and significantly improving inspection efficiency.

Achieves a measurement precision of 0.05mm, delivering dependable data for mechanical inspections.

In terms of measurement accuracy, the system achieves 0.05mm error control, which provides reliable data support for industrial scenes such as mechanical parts inspection and assembly accuracy verification, and helps to achieve refined quality control.

2.Light weight and Portable, Facilitating Long – term Operations

Aviation inspection often requires staff to hold equipment for extended periods to carefully observe various aircraft components. Traditional inspection equipment, if too heavy, can easily cause fatigue during operation. This not only reduces work efficiency but may also lead to negligence due to fatigue, potentially overlooking hidden safety hazards. The Yateks industrial endoscope takes this into account, keeping the overall weight within 2.0KG. This handheld and lightweight design significantly reduces the burden on the staff. Just as a doctor can use a lightweight stethoscope to conduct long – term diagnoses with ease, aviation inspectors can hold the Yateks industrial endoscope and perform detection work for several consecutive hours without significant arm soreness. This allows them to maintain a high level of focus and operational precision. For example, when inspecting aircraft turbine blades one by one, the staff can flexibly adjust the angle of the endoscope and operate stably for a long time, ensuring that no minor cracks or damages on any blade are overlooked.

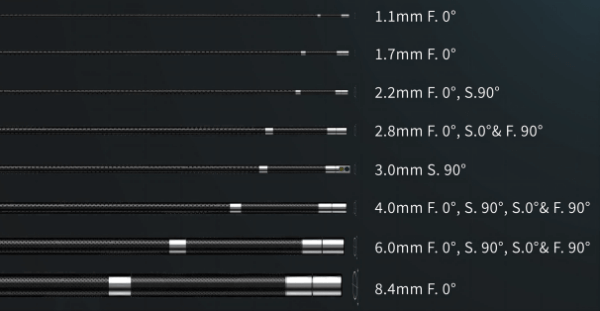

3.Diverse Lenses and diameter, Adaptable to Complex Aviation Components

The structure of an aircraft is extremely complex, and the inspection requirements for different components vary greatly. From the narrow gaps between turbine blades to the vast interior of the engine and the complex structure of the turbine, inspection equipment needs to be highly adaptable. The Yateks industrial endoscope offers a variety of lens diameters ranging from 0.85 – 8.4mm, and the longest pipeline can reach 20M, perfectly meeting various inspection scenarios. For the narrow gaps between turbine blades, the 0.85mm ultra – thin lens is like a highly skilled micro – sculptor, carefully penetrating into the gaps. Without damaging the blades, it clearly presents every detail on the blade surface, and even the tiniest cracks are exposed. When inspecting the interior of large components such as engines and turbines, the 8.4mm lens combined with the 20M long pipeline is like a flexible detection dragon, smoothly reaching the deep interior from the external entrance. It conducts a comprehensive and detailed scan of the entire interior space, ensuring that no corner is missed. Whether it is inspecting the assembly quality of engine internal components during the new aircraft manufacturing stage or the regular maintenance inspection of in – service engines, the Yateks industrial endoscope can perform tasks excellently with its diverse lens specifications.

4.High brightness,high resolution image, and Wide – angle depth of view, Penetrating dark and vast Spaces

The interior of an aircraft engine is a dark and spacious environment, and traditional inspection tools struggle to clearly observe the internal conditions in such an environment. The Yateks industrial endoscope is equipped with a high – brightness fiber optic light source, which is like a bright dawn, instantly penetrating the darkness and illuminating every corner of the engine interior as brightly as daylight. Even the deepest and most hidden parts can clearly reveal their true state. Super-wide viewing angle and super-large depth of field are suitable for inspection in various complex environments.Inspectors can quickly grasp the situation of a large – area region inside the engine without frequently moving the lens. For example, when inspecting the engine combustion chamber, by positioning the lens once and using its wide field of view, most of the inner wall can be observed, and problems such as ablation and carbon deposition can be discovered in a timely manner. The perfect combination of high – brightness lighting and a wide field of view greatly improves inspection efficiency, reduces inspection time, and also lowers the risk of missed detection due to limited vision.

5. Flexible Pipeline, Overcoming Obstacles in Pipeline Inspection

The interior of the engine is filled with crisscrossing and winding oil pipes. These pipelines are not only narrow but also have many bends, posing great challenges to inspection work. The Yateks industrial endoscope has a 360 – degree electro-motor articulation. As if it has a freely rotating “wrist,” enabling it to move freely through complex pipelines and easily handle various bends and narrow spaces. Whether it is a right – angled bend or a spiral – shaped oil pipe, it can flexibly adjust its direction and accurately deliver the lens to the position that needs inspection. Just like an experienced maze explorer, it can move freely in the intricate pipeline maze. During the inspection process, inspectors can easily control the steering of the pipeline through the operation handle and conduct a comprehensive observation of the inner wall of the pipeline, ensuring that problems such as inner wall corrosion, weld defects, and foreign matter blockages are discovered in a timely manner, providing strong support for the safe operation of the engine.

6.Durable & Replaceable Video Probes

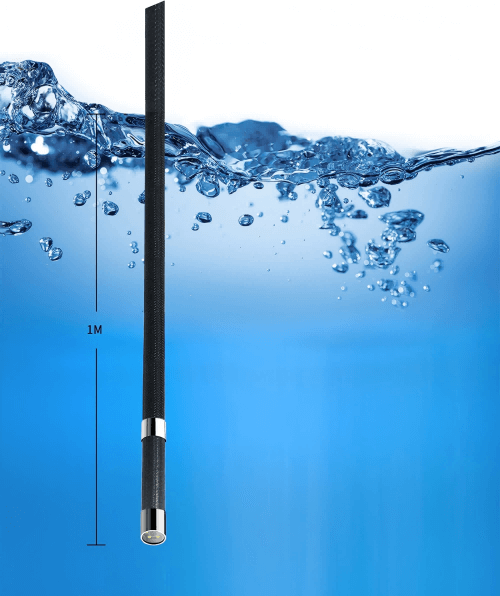

Robust and durable — the host has a rugged shell and structure, the probe IP67 level waterproof, the probe part of the use of special materials and processes, with good abrasion resistance and corrosion resistance.

7. Waterproof and Oil – resistant, Adaptable to Harsh Inspection Environments

The environment of aviation inspection work is often very complex, with oil stains and water vapor everywhere. Ordinary inspection equipment is easily damaged in such an environment, causing the inspection work to be unable to proceed normally. The Yateks industrial endoscope reaches an IP67 waterproof rating, which means it can effectively prevent dust intrusion and can be immersed in water 1 meter deep for 30 minutes without being affected. When facing the common harsh environments of oil stains and water vapor in aircraft engine inspections, the Yateks industrial endoscope can still operate stably and maintain excellent performance. Whether in an oil – filled environment inside the engine or when inspecting external aircraft pipelines that may come into contact with water vapor, it can reliably complete the inspection task, providing inspectors with accurate and clear images and demonstrating extremely high reliability and durability.

8.Convenient Data Transmission, Accelerating Inspection Result Analysis

In aviation inspection work, the timely transmission and analysis of inspection data are crucial for making maintenance decisions. The Yateks industrial endoscope supports two data transmission methods: Wifi wireless transmission and Type C data cable transmission, providing great convenience for fast data transfer. After the inspection is completed, the staff can choose the appropriate transmission method according to the actual situation. If immediate preliminary analysis of the inspection results is required, the inspection records can be transmitted in real – time to a computer or mobile phone via Wifi. On – site, images and videos can be quickly viewed, and the discovered problems can be preliminarily evaluated. For the in – depth analysis and archiving of a large number of high – definition images and video files, the TypeC data cable can be used to quickly copy them to the computer. This efficient data transmission method greatly shortens the time from inspection to conclusion, provides strong support for timely formulation of maintenance plans, helps improve aircraft maintenance efficiency, reduces aircraft downtime, and lowers operating costs.

9.Sturdy Packaging, Easy to Carry for On – demand Inspection

For aviation maintenance teams, it is common to carry equipment to different airports and maintenance sites for inspection work. The sturdy black box packaging equipped with the Yateks industrial endoscope not only provides comprehensive protection for the equipment, effectively preventing damage from collisions and squeezes during transportation but also meets aviation transportation standards and can be directly carried onto the aircraft. It is like equipping inspectors with a “mobile inspection station.” Whether they are going to remote domestic airports or overseas maintenance sites, they can easily carry the equipment and conduct inspection work at any time. This convenience greatly improves the timeliness and flexibility of services, ensuring that when problems occur with the aircraft, a rapid response can be made, and timely inspection and maintenance can be carried out to ensure the normal operation of flights.

The Yateks Realta 3D Industrial Endoscope makes inspection data clear at a glance with its high-precision measurement technology and 6S production measurement cloud map. Its high-brightness and high-definition imaging ensures that even the tiniest defects are impossible to hide. Additionally, its portable design allows it to easily adapt to complex environments, while its convenient data processing and transportation features enhance overall efficiency. Whether it’s ensuring flight safety or revolutionizing the aviation maintenance inspection experience, the Yateks Industrial Endoscope helps the aviation industry reach new heights with its intelligent and efficient advantages!

Application case sharing in aviation field: nondestructive testing of civil aircraft engines and turbine blades

Case background:

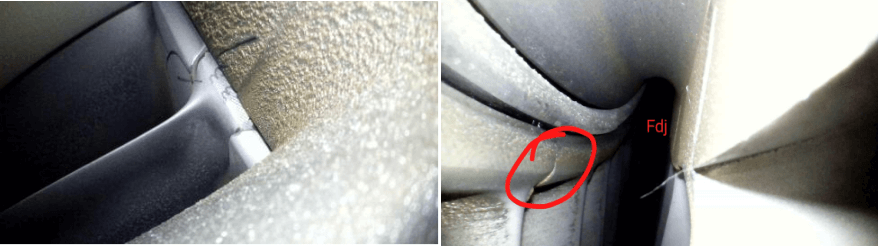

When a civil airline regularly overhauls the engine of a passenger plane, it is necessary to detect whether there are cracks, wear and foreign body residues in the internal components such as turbine blades and combustion chambers. Traditional disassembly detection is costly and time-consuming, and may cause secondary damage to precision parts.

Application proposal:

Tool selection: use Yateks Realta 3D industrial endoscope (equipped with high-resolution lens and 3D measurement function).

Detection process:

The endoscope probe is inserted through the engine manhole, and the internal image is transmitted in real time by using high-brightness LED light source and high-definition imaging technology.

When a suspected crack or worn part is found, the 3D measurement function is enabled to accurately obtain the defect size (such as length, area and depth), and it only takes 6 seconds to quickly generate the measurement cloud chart record data.

Compare the historical test data, evaluate the deterioration trend of components, and judge whether maintenance or replacement is needed.

Application value

Efficiency improvement: The time consumption of a single inspection is shortened from 24 hours of traditional disassembly to 3 hours, which greatly reduces the downtime cost.

Accuracy: 3D measurement error is 0.05 mm, so as to avoid excessive maintenance or missed inspection caused by manual judgment error.

Safety: Non-contact detection avoids component damage and ensures flight safety.

How to learn more about Yateks Realta 3D measurement industrial endoscope information and specifications?

Please visit the link below our official website directly, or send an email([email protected])directly to our marketing department for more information.