In the world of steel and pipelines, large condensers act as silent “cooling hearts,” tirelessly ensuring the stable operation of critical systems in power plants, chemical industries, and ships. However, hidden threats like scaling, corrosion, cracks, and blockages within the pipes can drastically reduce efficiency, cause leaks, or even lead to catastrophic failures. Traditional inspection methods—requiring shutdowns, disassembly, and tube extraction—are not only time-consuming and costly but also disrupt production schedules, resulting in losses worth millions!

Yateks Industrial Endoscope offers a “non-invasive” solution for in-depth condenser inspections.

Why Choose Yateks Industrial Endoscope?

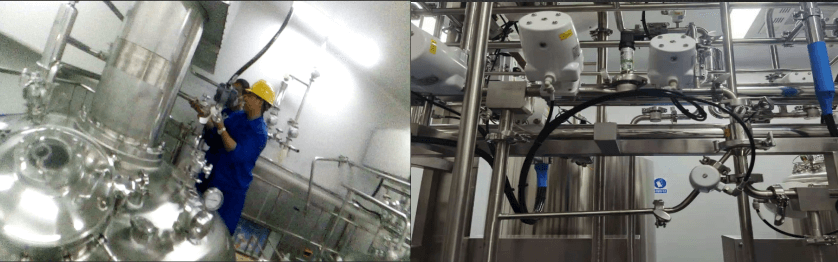

1.No Shutdown Required

2.With ultra-slim and flexible probes (as small as 0.7mm–8.4mm in diameter), our endoscope easily navigates complex condenser tubes while operations continue uninterrupted.

3.High-Definition Internal Inspection

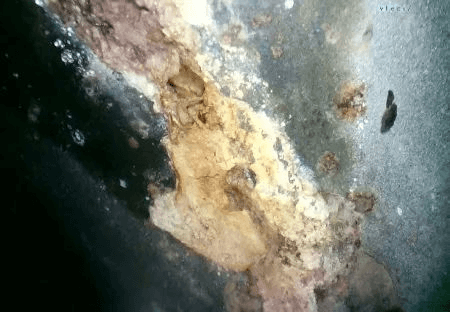

4.Equipped with millions of pixels and ultra-bright lighting, it reveals:

Scale buildup thickness

Depth of corrosion pits

Hidden micro-cracks

Weld integrity

Tube sheet leaks

Visual proof in inspection reports—no guesswork!

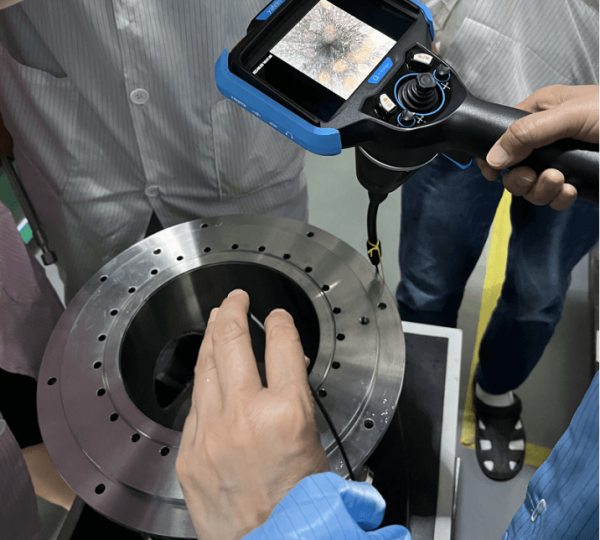

Precise Problem Identification

Advanced models feature 3D measurement, accurately calculating corrosion depth, crack length, and blockage area—providing scientific data for maintenance decisions.

Real-World Success Story

A major petrochemical research institute needed to inspect condenser pipes for corrosion, residue, scratches, and cracks. The setup included hundreds of interconnected tubes (5–8m long), with water flowing from one end to the other.

Solution:

Using Yateks’s Q-Series Industrial Endoscope (6mm diameter, 8m length tube), they completed the inspection of dozens of condensers in half a day, identifying 15 high-risk corroded tubes—preventing over $1 million in losses!

Economic Benefits of Yateks Industrial Endoscope

✔ 60% Lower Labor Costs – Only 1-2 inspectors needed, eliminating large disassembly teams.

✔ Optimized Maintenance Costs – Targeted repairs instead of blind replacements.

✔ Zero-Risk Inspection – No need for personnel to enter high-temperature, high-pressure, or chemically hazardous spaces.

✔ Preventive Maintenance – Regular endoscope “check-ups” detect issues early, extending equipment lifespan and ensuring continuous production.

The Future of Condenser Maintenance

Yateks Industrial Endoscope is revolutionizing large condenser inspections with its non-invasive, precise, efficient, and safe technology. It’s not just a problem detector—it’s a guardian of operational efficiency, safety, and cost savings. Upgrade to smarter inspections today!